leading manufacturer and supplier

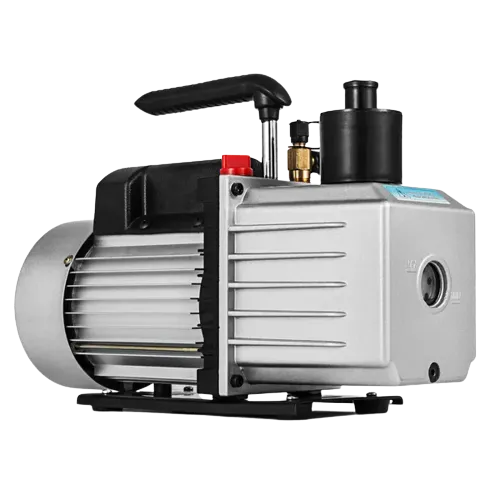

Rotary Vane Pumps Manufacturer

Applications

Application of Rotary Vane Vacuum Pump

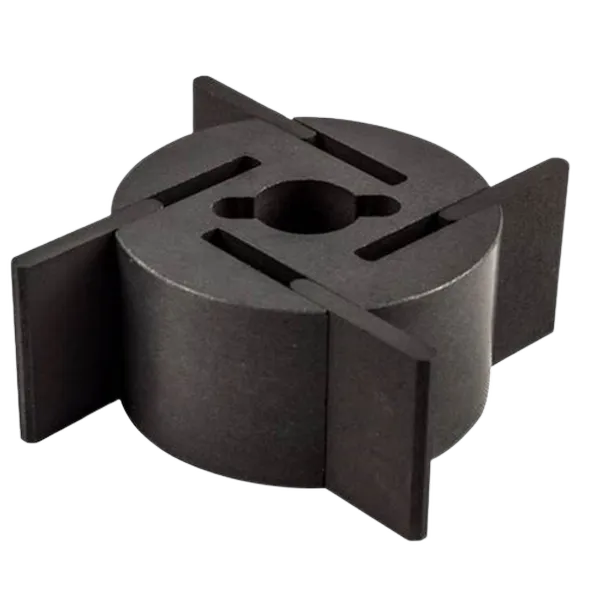

Rotor

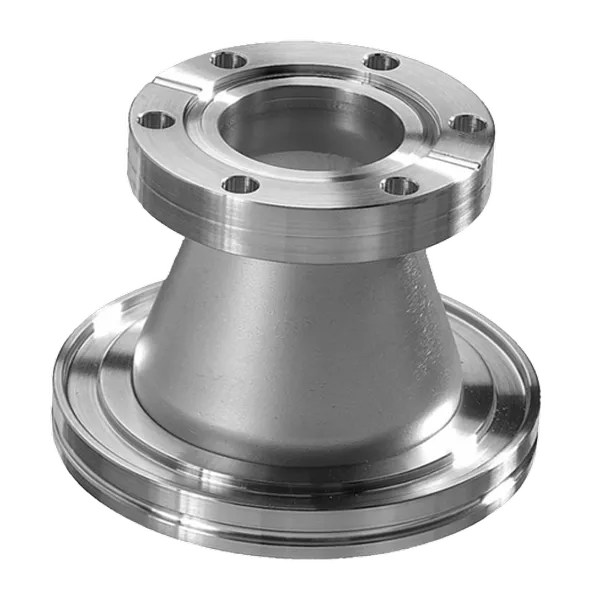

Suction Flange

Blades and Vanes

Motor

common components

What are the parts of a Rotary Vane Vacuum Pump?

The inlet valve, if available, is designed as a vacuum safety valve that is always open during operation. As the rotor turns, gas flows into the enlarging suction chamber until the second vane seals it off. The enclosed gas is compressed until the outlet valve opens against atmospheric pressure. The outlet valve is oil-sealed. When the valve is open, a small amount of oil enters the suction chamber, lubricating it and sealing the vanes against the housing (stator).

Types

Types of Rotary Vane Vacuum Pumps

Single Stage Rotary Vane Vacuum Pump

Double Stage Rotary Vane Vacuum Pump

Working Principle

The Working Principle of Rotary Vane Vacuum Pump

The rotor and the vanes divide the working chamber into two separate spaces with variable volumes. As the rotor turns it, the trapped gas flows into a suction chamber until the second vane seals it off. Then the enclosed gas is compressed until the outlet valve opens aligned with atmospheric pressure. In a gas ballast operation, a hole to the outside is then extended to empty into a sealed suction chamber on the front side of the pump.

Featured Products

Rotary Vane Pumps for Sale

benefits

What are the benefits of rotary vane vacuum pumps?

Lubrication prevents wear

Corrosion protection

Video

Watch Vacuum Pumps Video

FAQ

Knowledge About Rotary Vane Vacuum Pump

Differences Between Single Stage And Double Rotary Vane Vacuum Pumps?

The high rate of oil flow in the atmospheric level of hydraulic noise in the high vacuum stage does not exist. The lThe low oil flow rate makes the double rotary vane vacuum pump suitable for working under intense pressure and not for continuous work under high pressure. Even in the absence of town gas, the double rotary vane vacuum pump noise level is generally lower than the single-stage rotary vane vacuum pump.

Applications of Rotary Vane Vacuum Pumps?

(1) Chemical and pharmaceutical processes – degassing, crystallization, drying, distillation, evaporation, supercooling, fractionation, impregnation, vacuum coating (sublimation), and vacuum filtration.

(2) Environmental engineering – Aeration, dust extraction systems, and drying.

(3) Food processing – cutting machines and bottling and filling machines.

(4) Industrial applications – Vacuum hold down, dust extraction systems, drying systems, and industrial furnaces.

(5) Packaging industry – Centralized vacuum systems and packaging machines.

(6) Pneumatic conveying

(7)Woodworking industry – dust extraction systems and vacuum hold down.

(1) Environmental engineering – Aeration.

(2) Industrial applications – Lifting and holding and picking and place.

(3) Packaging industry – Packaging machines.

(4) Printing industry – Post-press applications and printing presses.

(5) Woodworking industry – Vacuum holds down.