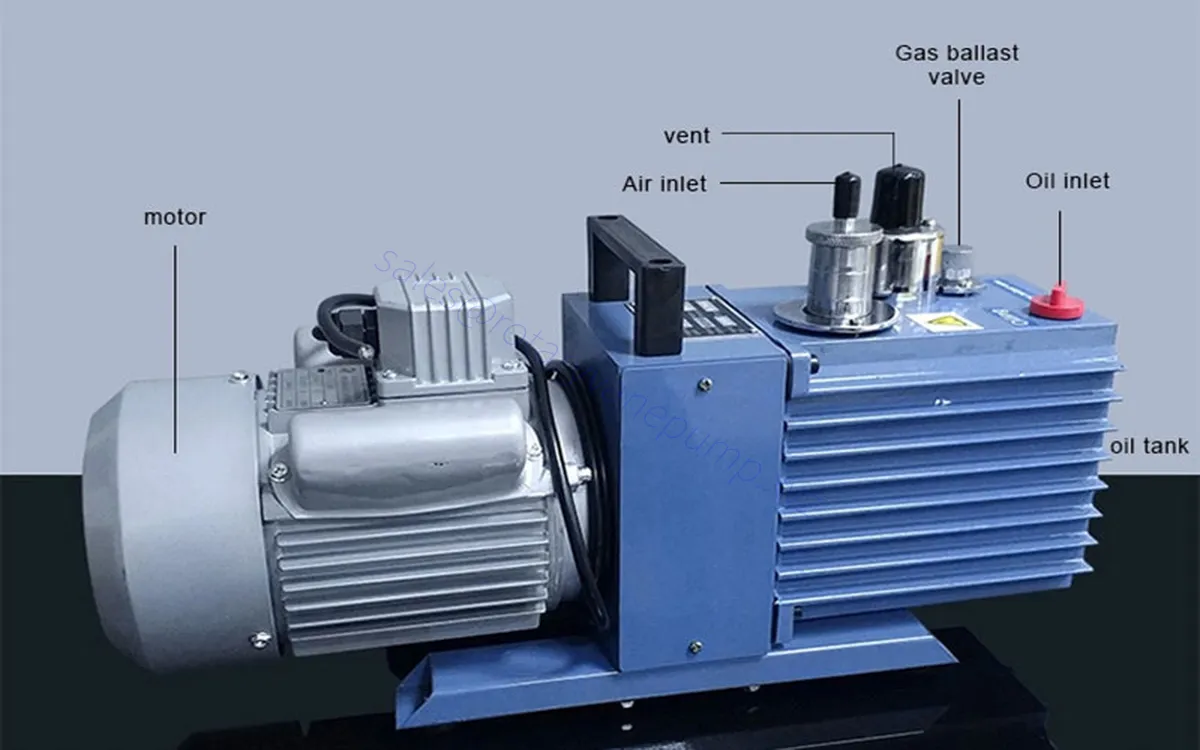

Rotary Vane Pumps

2XZ Series Rotary Vane Vacuum Pump

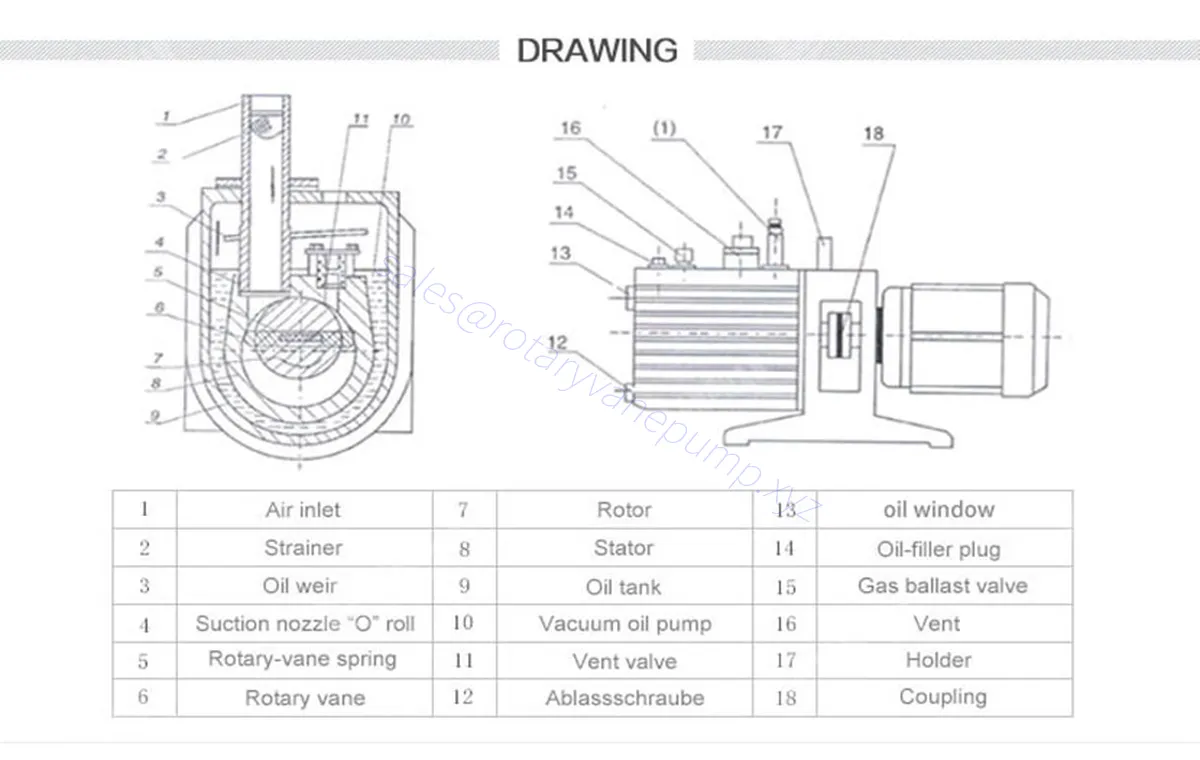

2XZ-series industrial-grade dual-stage vacuum pumps are designed for reliable long time continuous operation. They have a balance between low cost and high performance. They come with gas ballast, which is designed to allow the purposefully pull off a less profound and slower vacuum by opening the gas ballast, allowing dry air to go directly into the pump and diluting the vacuum pull; it also helps keep moisture, solvent, and other contaminants from getting stuck in the pump, and instead passing through to the exhaust. The built-in check valve prevents pump oil backflow.

As one of the rotary vane pump manufacturers, suppliers, and exporters of mechanical products, We offer rotary vane pumps and many other products. Please get in touch with us for details.

Mail:[email protected]

2XZ-series industrial-grade dual-stage vacuum pumps are designed for reliable long time continuous operation. They have a balance between low cost and high performance.

They come with gas ballast, which is designed to allow the purposefully pull off a less profound and slower vacuum by opening the gas ballast, allowing dry air to go directly into the pump and diluting the vacuum pull; it also helps keep moisture, solvent, and other contaminants from getting stuck in the pump, and instead passing through to the exhaust. The built-in check valve prevents pump oil backflow.

We offer all necessary fittings (KF25 clamps, hose barb connectors, etc.) and a high-capacity exhaust oil mist filter that returns trapped pump oil back to the pump and makes the pump quieter to run.

It is important to note that pumps should always be run in ventilated areas.

Features of Rotary Vane Vacuum Pump

- it can play a separate role and can also be used as various types of high-vacuum systems of the pre-pump and pre-pump.

- The inlet’s continuous open-air operation shall not exceed three minutes.

- The pump does not apply to the extraction of metal corrosive; the chemical reaction of the oil from the pump, containing dust particles of gas to the body oxygen, is too high, and there is an explosive gas.

- The pump has to be used for compression pump or pump.

- Working environment: temperature 5 ℃ -40 ℃ range, the relative temperature is not greater than 90%, and inlet pressure less than 1333Pa under the conditions allow long-term continuous operation.

- For the installation of the power supply, according to the provisions of the motor tag wiring, the motor rotation should be noted in the direction of the arrow on the bearing is the same direction.

- In continuous pumping container pipe, the diameter should not be less than the pump inlet diameter, and the line should be short and less elbow while paying attention to pipeline leakage.

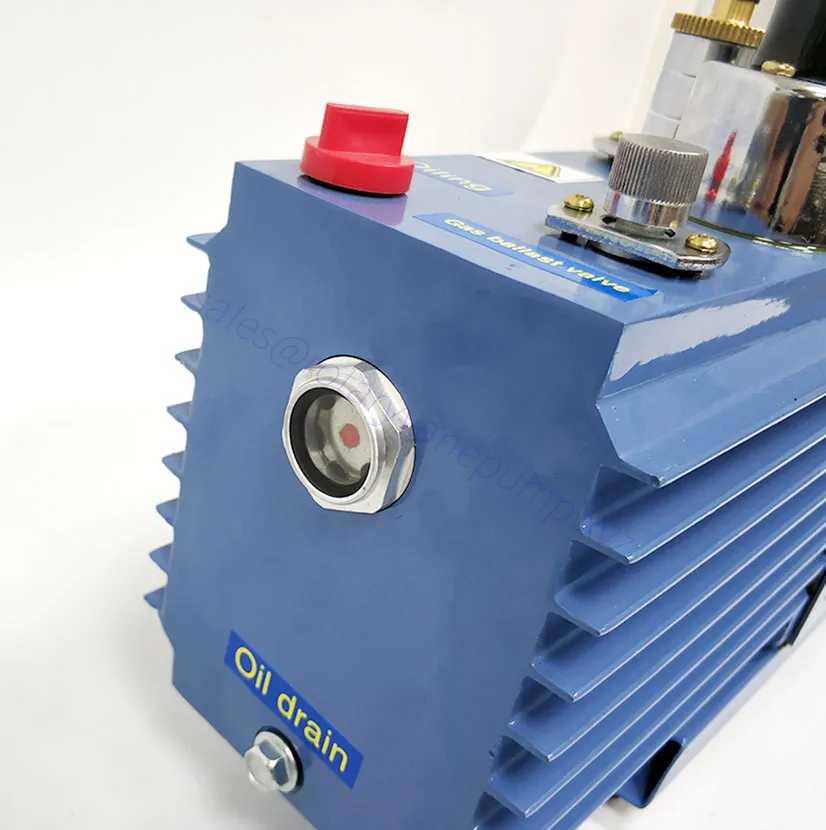

- Before each start focusing on the oil level, stopping the pump oil to the oil standard glass diameter of 4/5 height is appropriate.

Detail images

|

|

|

|

|

|

Specific Parameters

| Model | 2XZ-0.5 | 2XZ-1 | 2XZ-2 | 2XZ-4 | 2XZ-8 | 2XZ-15 | |

| Pumping speed (L/S) | 0.5 | 1 | 2 | 4 | 8 | 15 | |

| Ult. vacuum (Pa) | Without gas ballast | ≤6*10-2 | |||||

| With gas ballast | ≤6.5 | ≤1.33 | |||||

| Rotary speed (r/min) | 1400 | 1410 | 1410 | ||||

| Working Voltage (V) | 220 | 220/380 | |||||

| Motor power (kW) | 0.18 | 0.25 | 0.37 | 0.55 | 1.1 | 1.5 | |

| Inlet diameter (mm) | Φ16 | Φ16 | Φ25 | Φ25 | Φ40 | Φ40 | |

| Temp. rise of pump oil (℃) | 40 | ≥45 | ≥65 | ≥70 | |||

| Oil capacity (L) | 0.5 | 0.55 | 0.8 | 0.1 | 2.5 | 4.0 | |

| Size | L (mm) | 445 | 467 | 488 | 528 | 575 | 703 |

| W (mm) | 130 | 130 | 145 | 145 | 172 | 338 | |

| H (mm) | 254 | 254 | 280 | 280 | 350 | 453 | |

| Weight (kg) (with 3-phase motor) | 13.5 | 15 | 20 | 23 | 48.5 | 77.5 | |

| Noise (db) | ≥60 | ||||||

| Vibration reference number (u) | ≥80 | ||||||