Product Description

2XZ-2

Physical Property

| Voltage | 220V/50HZ | Displacement | 4CFM |

| Voltage | 110V/60HZ | Displacement | 6CFM |

| Ultimate Vacuum | 6X10-2PA | Motor Power | 1/2HP |

| Fuel | Electric | Oil Capacity | 1000ML |

| Dimension | 514X168X282mm | Usage | Air Pump |

| Structure | Double-stage Vacuum Pump | Color | Black |

| N.W.(1 Set) | 22Kg | Package Size | 60X21X32cm |

Application

The application is wide, such as vacuum refrigeration, refrigerant recovery device, tea packaging, air conditioner, automobile reparation, medical research equipment, packaging and printing equipment, scientific research, semi-conductor and etc.

Main Features

1) It can work in low temperature environment,even in cold winter.

2) Unlike the traditional ones ,RS series are much lighter,which is easy to carry.

3) RS series are attractive design in its outlook,looks more fashionable.

HangZhou CHINAMFG Refrigeration Technology Co., Ltd. is a large modern chemical enterprise specializing in manufacturing, researching and exporting high purity fluoro-chemicals, fine chemicals, hydrocarbon chemicals, etc. Its headquarter locates in ZheJiang capital HangZhou city, and has 2 profound manufacturing bases, separately in HangZhou City of ZheJiang Province and HangZhou city of ZHangZhoug Province. Our company takes “Science and Technology, Environmental Protection, Internationalization” as development direction and “First-class Technology, First-class Quality, First-class Service, First-class Efficiency” as service tenet.

Main Products:

R22 , R134A , R410A , R407c , R507 , R404A , R600 Refrigerant Gas, Manifold Gauge ,vacuum pump, compressor, etc.

Customer’s satisfactory is our forever pursue

FAQ

Q: If there’s space for you to lower the price?

A: The price in that field is changeable, so, fell free to ask for latest price and I’ll provide you the lowest.

Q: Could I use my own LOGO or design on the goods?

A: Of course, Customized logo and design on mass production are available.

Q: Can I visit your factory?

A: Sure, you can come at any time. We can also pick you up at airport or at the station.

Q: What is the delivery time?

A: One week for sample, 15 to 20 days for mass production.

Q: How about the payment term?

A: TT, L/C at sight, Paypal, Western Union, etc. Normally 30% T/T in advance, 30% TT before shipment, the balance against the copy of B/L in 7 days.

Q: How much discount can you offer?

A: We will do our best to offer the competitive price, the discount usually depends on the quantity.

Q: The shipping fare costs too much ,can you make it cheaper for us?

A: We will try our best to negotiate with shipping company,we save every penny for our customers,if it is possible ,you can designate your own shipping agency.

Q: Can I trust you?

A: Absolutely YES. We are “made in china” verified supplier.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Oil or Not: | Oil Free |

|---|---|

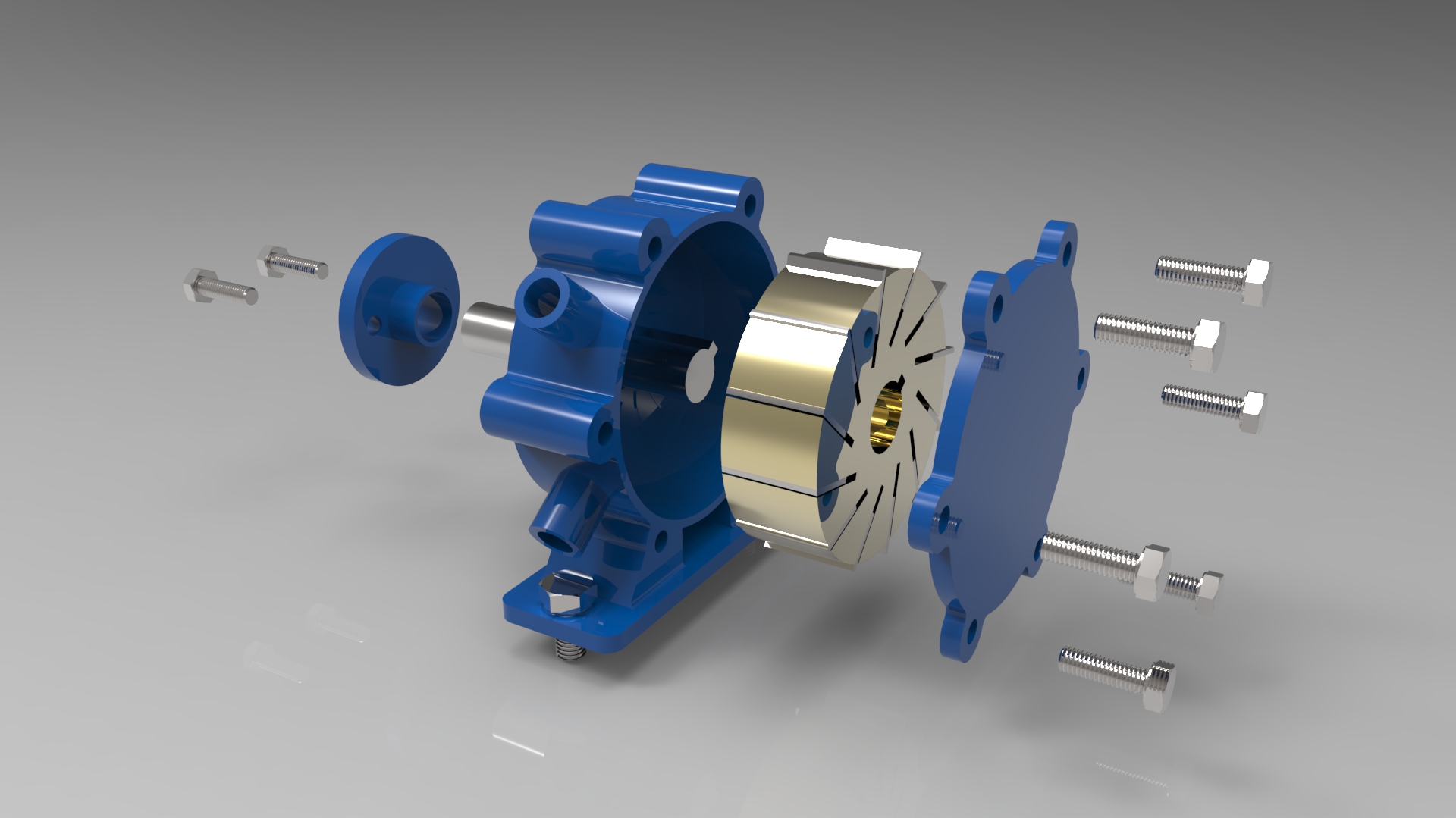

| Structure: | Rotary Vacuum Pump |

| Exhauster Method: | Entrapment Vacuum Pump |

| Vacuum Degree: | High Vacuum |

| Work Function: | Mainsuction Pump |

| Working Conditions: | Dry |

| Samples: |

US$ 35/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

What Is the Role of Lubrication in Rotary Vane Pump Operation?

Lubrication plays a critical role in the operation of a rotary vane pump, ensuring its smooth and efficient performance. Here’s a detailed explanation of the role of lubrication in rotary vane pump operation:

– Friction Reduction: The primary function of lubrication is to reduce friction between moving parts within the pump. In a rotary vane pump, the vanes slide in and out of the rotor slots as the rotor rotates. Lubrication forms a thin film between the vanes and the rotor, reducing the friction and allowing smooth movement. This friction reduction minimizes wear and tear on the vanes and rotor, contributing to the longevity of the pump.

– Seal Enhancement: Lubrication also helps in creating a tight seal between the vanes and the pump housing. The lubricant fills any gaps or imperfections, ensuring proper sealing and preventing gas or fluid leakage. This is particularly important for achieving and maintaining the desired vacuum levels in the pump. Effective sealing enhances the pump’s efficiency and performance.

– Heat Dissipation: During operation, a rotary vane pump generates heat due to the friction and compression of gases or fluids. Lubrication helps in dissipating this heat by absorbing and carrying it away from the critical components of the pump. It prevents excessive heat buildup that can lead to component damage or reduced performance. Proper lubrication ensures that the pump operates within the desired temperature range.

– Wear Protection: The lubricant forms a protective layer on the surfaces of the vanes, rotor, and other moving parts. This layer acts as a barrier, minimizing direct metal-to-metal contact and reducing wear and tear. It helps prevent damage to the vanes and rotor caused by friction and ensures the longevity of these components. Lubrication also protects against corrosion and helps maintain the overall integrity of the pump.

– Noise Reduction: Lubrication contributes to noise reduction in a rotary vane pump. The smooth movement facilitated by the lubricant minimizes vibrations and eliminates or reduces unwanted noise generated during operation. This is particularly important in applications where low noise levels are desired, such as laboratory or medical settings.

– Performance Optimization: Proper lubrication is crucial for maintaining the pump’s performance and efficiency. It ensures that the pump operates with minimal resistance and energy loss, allowing it to achieve the desired vacuum levels or fluid flow rates effectively. Lubrication helps optimize the pump’s overall performance and contributes to its reliability and effectiveness in various applications.

It’s important to note that using the correct type of lubricant specified by the pump manufacturer is essential. Different rotary vane pumps may have specific lubrication requirements, including the type of lubricant and recommended lubrication intervals. Adhering to these guidelines ensures that the lubrication effectively fulfills its role and maintains the pump’s optimal operation.

What Are the Typical Applications of Rotary Vane Pumps?

Rotary vane pumps find application in various industries and sectors due to their versatility and reliable performance. Here’s a detailed explanation of the typical applications of rotary vane pumps:

– Industrial Manufacturing: Rotary vane pumps are commonly used in industrial manufacturing processes. They are employed for tasks such as vacuum packaging, vacuum drying, vacuum distillation, and vacuum filtration. The pumps assist in creating and maintaining the necessary vacuum levels for these manufacturing operations.

– HVAC Systems: Rotary vane pumps play a crucial role in heating, ventilation, and air conditioning (HVAC) systems. They are utilized for tasks such as evacuating air and moisture from refrigeration and air conditioning systems during installation or maintenance. Rotary vane pumps ensure proper system performance and prevent issues like refrigerant contamination.

– Laboratory and Scientific Research: Rotary vane pumps are widely used in laboratory settings and scientific research facilities. They are employed in applications such as vacuum ovens, freeze drying, sample preparation, and vacuum distillation. Rotary vane pumps provide the necessary vacuum conditions for experiments, sample processing, and equipment operation.

– Medical and Healthcare: Rotary vane pumps find application in the medical and healthcare industry. They are used in medical devices such as vacuum suction units, blood analyzers, and laboratory equipment. Rotary vane pumps assist in creating a vacuum for various medical procedures, diagnostics, and research activities.

– Automotive: Rotary vane pumps are utilized in automotive systems, particularly in vehicles with diesel engines. They are commonly employed as vacuum pumps for brake boosters, which enhance braking performance. Rotary vane pumps ensure reliable vacuum supply for effective braking, contributing to vehicle safety.

– Printing and Packaging: Rotary vane pumps are employed in printing and packaging industries. They are used for tasks such as vacuum hold-down in printing presses and vacuum packaging of products. Rotary vane pumps facilitate the precise handling of paper, cardboard, and other materials during printing and packaging processes.

– Food and Beverage Processing: Rotary vane pumps find application in the food and beverage industry. They are utilized for tasks such as vacuum packaging of perishable products, vacuum degassing of liquids, and vacuum filling of bottles or containers. Rotary vane pumps contribute to extending the shelf life of food products and ensuring their quality.

– Environmental Applications: Rotary vane pumps are utilized in environmental applications such as air sampling and monitoring equipment. They assist in creating a vacuum for sampling air pollutants, analyzing air quality, and conducting environmental research.

– Semiconductor Manufacturing: Although rotary vane pumps may not be suitable for ultra-high vacuum applications in semiconductor manufacturing, they still find utility in certain stages of the process. They are often used for tasks such as load-lock operations, wafer handling, and general vacuum needs that do not require extremely low pressures.

– Other Applications: Rotary vane pumps have additional applications in areas such as power generation, oil and gas, chemical processing, pharmaceutical production, and wastewater treatment. They are employed for various tasks involving vacuum generation, fluid handling, and system evacuation.

In summary, rotary vane pumps have diverse applications across industries, including industrial manufacturing, HVAC systems, laboratory research, medical and healthcare, automotive, printing and packaging, food and beverage processing, environmental monitoring, and more. Their reliable performance, versatility, and ability to create vacuum make them valuable in numerous applications and processes.

editor by CX 2024-03-28

by

Tags:

Leave a Reply