Product Description

Product Description

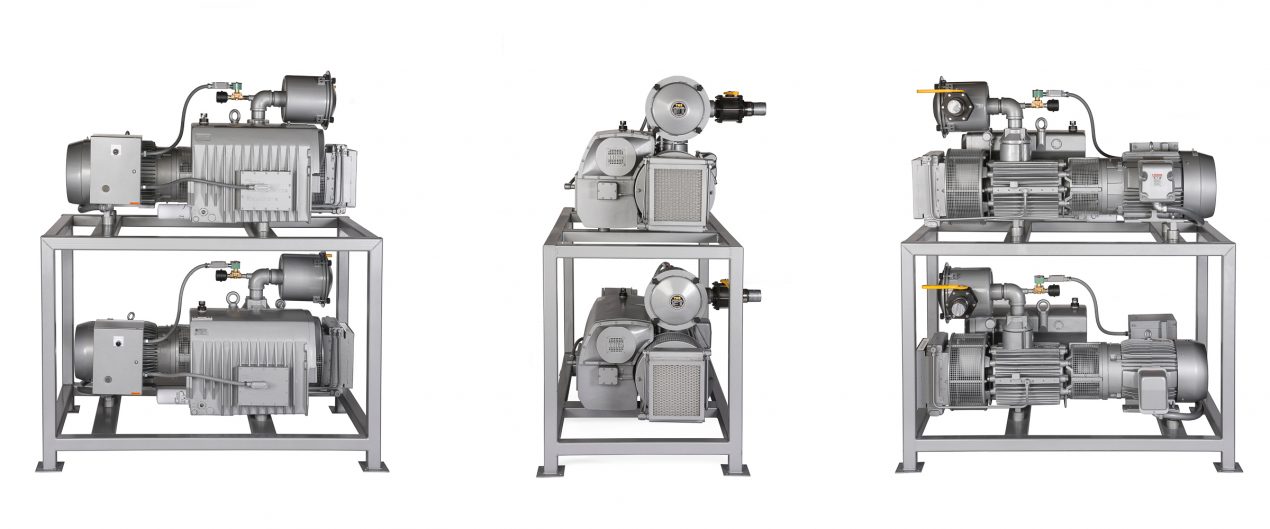

Our vane pumps are exported to the USA, Europe, Iran, Saudi Arabia, South Africa, Canada, Germany, Belgium, etc.

Our pump is the same as the original with high pressure, lower noise, and better performance. All parts can be replaced with the original, such as the cart kit, shaft, seal, bearing, etc. It can be applied in heavy equipment, most hydraulic systems such as plastic injection machinery, rubber machinery, casting machinery and machine tool industry, shoe machinery, and mining machinery.

Products Features

1)New original authentic, excellent quality.

2)With high efficiency, no vibration, low noise, stable performance, easy to heat, wear resistance, long life, and other characteristics.

3)Simple operation and easy maintenance.

PFE Single Pump Model Designation

|

PFE- |

41 |

045/ |

1 |

D |

TO |

|

PFE series fixed displacement vane pump |

Series |

Single pump geometric displacement(ml/r) |

Shaft type |

Direction of rotation view from shaft end |

Port orientation |

|

PFE single pump series |

21 |

5,6,8,10,12,16 |

1-Cylindrical type(standard) 2-Cylindrical type(ISO/DIS3019) 3-Cylindrical type(high torque) 5-Splined type |

D-CW S-CCW |

See port orientation table(inlet and outlet ports can be oriented in any of 4 relative positions:T,V,U,W) |

|

31 |

16,22,28,36,44 |

||||

|

41 |

29,37,45,56,70,85 |

||||

|

51 |

90,110,129,150 |

||||

| 61 | 160,180,200,224,250 | ||||

| 22 | 8,10,12 | ||||

| 32 | 22,28,36 | ||||

| 42 | 45,56,70 | ||||

| 52 | 90,110,129 |

PFED Double Pump Model Designation

| PFED- | 4131 | 045/ | 571/ | 1 | D | TO |

| PFED series fixed displacement vane pump | Series | Double pump geometric displacement(ml/r) | Double pump geometric displacement(ml/r) | Shaft type | Direction of rotation view from shaft end | Port orientation |

| PFED double series | 3121 | 16,22,28,36,44 | 5,6,8,10,12,16 | 1-Cylindrical type(standard)

2-Cylindrical type(ISO/DIS3019) 3-Cylindrical type(high torque) 5-Splined type 6-Spline type |

D-CW

S-CCW |

See port orientation table(inlet and 2 outlet ports can be oriented in any of 30-2 relative positions:TO, VG) |

| 4121 | 29,37,45,56,70,85 | 5,6,8,10,12,16 | ||||

| 4131 | 29,37,45,56,70,85 | 16,22,28,36,44 | ||||

| 5121 | 90,110,129,150 | 5,6,8,10,12,16 | ||||

| 5131 | 90,110,129,150 | 16,22,28,36,44 | ||||

| 5141 | 90,110,129,150 | 29,37,45,56,70,85 |

Product Application

It can be applied in heavy equipment, most hydraulic systems such as plastic injection machinery, rubber machinery, casting machinery and machine tool industry, shoe machinery, and mining machinery.

Company Profile

HangZhou CHINAMFG International Trade Co.,Ltd specialize in high-end hydraulic pump products for more than 8 years. Our company is located in the Yangtze River Delta, adjacent to ZheJiang . It is about 2 hours drive from ZheJiang Xihu (West Lake) Dis. International Airport and 45 minutes from HangZhou Shuofang Airport. The transportation is very convenient and the location is very superior.

The main products of our company are Dennison T6, T7 series vane pumps; CHINAMFG V, VQ series; CHINAMFG SQP series vane pumps; CHINAMFG PV2R series hydraulic vane pumps; V10, V20 series vane pumps; Gear pumps; High-pressure piston pumps; CHINAMFG valves; Motor series and parts.

Our products can be widely used in engineering machinery, rubber and plastics machinery, agricultural machinery, shoe machinery, casting machinery, metallurgical machinery, mining machinery, metal cutting machine tools, sheet metal equipment, packaging machinery, ship machinery, port machinery, drilling equipment and other various types of the hydraulic system.

All of our products are fully inspected and tested before delivery in order to make sure all of our products are of good quality and performance. After qualified, they can be shipped out. After being detected by the authoritative state department, the performance, and technical indicators of our products have reached or exceeded the similar products made by the domestic and foreign top manufacturers and can be interchangeable, instead of original imported products. Lower noise, higher volume efficiency, longer life, and reasonable price have been praised our products by all of our domestic and overseas customers.

As 1 of the reliable suppliers in China, We have keeping improved our management & technology levels. Up to now, we have earned a good reputation in domestic and abroad market. And our products have been exported to many countries, like Canada, America, Argentina, Chile, Brazil, Spain, Saudi Arabia, Korea, Thailand, Malaysia, Indonesia, Russia, India, and so on.

Quality and honesty are our foundation, customer satisfaction is our job, to get a “Win-Win” is our main target. We always focus on improving our quality.

We believe our quality and service will bring success to each customer.

Welcome final users and distributors from all over the world to contact us and create success

With your support and our effort, we deeply believe that tomorrow of CHINAMFG Hydraulic will be much better.

Packaging & Shipping

We can provide cartons, wooden pallets,s or wooden case packing. Also, we can customize packaging according to your needs, welcome to contact us!!! Please consult customer service for other payment methods and logistics details.

FAQ

Q1: Why do we buy from CHINAMFG HYDRAULIC?

A: No 1 can match our dedication to quality. honesty and value.

* Experienced hydraulic pump experts, experienced customer service, experienced technicians dedicated to their work, process each and every order.

* Each order is carefully inspected before it leaves our facility. Parts are matched to OEM specifications, and units are fully tested to flow, pressure, and torque.

* We understand that each order placed, is important. We promise to ship the right part, the first time, on time as promised.

Q2: Which parts do you provide?

A: We mainly provide hydraulic pumps ( vane pumps, gear pumps, piston pumps), hydraulic valves(such as CHINAMFG valves), and servo systems (servo pump/servo motor). For more details, please visit PRODUCTS.

Q3: Is your company accept customization?

A: We could accept OEM depending on the quantity

Q4: My parts did not show up in your search bar, can you supply them?

A: More Than Likely! While we strive to maintain as many online items as possible, hundreds of thousands of products are not listed online. Please contact us on Made-in-China, or call us.

Q5: How long is your warranty?

A: All our products come with a 1 (1) year warranty.

Q6: What is your delivery time?

A: It depends on whether the products you buy are in stock.If in stock, we will ship it within 3-5 days; if not, for orders with large quantities, within 30 days. For the exact lead time, please contact customer service for confirmation.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Online Technical Support |

|---|---|

| Warranty: | 1year |

| Acting Form: | Single-Acting |

| Type: | Vane Pump |

| Displacement: | Dosing Pumps |

| Performance: | No Leak |

| Customization: |

Available

|

|

|---|

Are There Oil-Free Rotary Vane Pump Options Available?

Yes, there are oil-free rotary vane pump options available in the market. These pumps are designed to operate without the need for lubricating oil, offering certain advantages and applications where oil contamination is a concern. Here’s a detailed explanation:

– Dry Vane Technology: Oil-free rotary vane pumps, also known as dry vane pumps, utilize specialized dry vane technology. Instead of relying on lubricating oil to create a seal and reduce friction, these pumps use self-lubricating materials and innovative design features to achieve efficient operation without oil.

– Reduced Contamination Risk: One of the primary advantages of oil-free rotary vane pumps is that they eliminate the risk of oil contamination. In certain applications, such as in the food and beverage industry, pharmaceutical production, or cleanroom environments, maintaining a completely oil-free and contaminant-free operation is critical. Oil-free rotary vane pumps address these requirements and ensure the purity and integrity of the process or product being handled.

– Environmental Friendliness: Oil-free rotary vane pumps are considered more environmentally friendly compared to their oil-lubricated counterparts. The elimination of oil lubrication means there is no risk of oil leaks or spills, reducing the potential impact on the environment. These pumps also eliminate the need for oil changes and disposal, resulting in lower maintenance and disposal costs.

– Lower Operating Costs: Oil-free rotary vane pumps can offer cost advantages in terms of operating expenses. Since they do not require oil lubrication, there is no need to purchase, monitor, or replace oil. This can result in savings over the pump’s lifetime. Additionally, oil-free pumps often have lower maintenance requirements, as there is no need to monitor oil levels, change oil, or replace oil filters.

– Application Flexibility: Oil-free rotary vane pumps are suitable for a range of applications where oil contamination must be avoided. They find application in industries such as food and beverage, pharmaceuticals, medical devices, laboratory research, electronics manufacturing, and other sensitive environments. These pumps can handle both gas and some liquid applications, providing versatility in various processes.

– Considerations: While oil-free rotary vane pumps offer several advantages, it’s important to consider certain factors when choosing these pumps. They may have slightly different operating characteristics compared to oil-lubricated pumps, such as lower ultimate vacuum levels or reduced performance in high-pressure applications. It’s crucial to assess the specific requirements of the application and consult the manufacturer’s specifications to ensure the chosen oil-free rotary vane pump meets the desired performance criteria.

– Alternative Technologies: In cases where oil-free rotary vane pumps may not be suitable, alternative technologies such as dry screw pumps or dry claw pumps can be considered. These pumps also offer oil-free operation and have their own unique advantages and applications.

In summary, oil-free rotary vane pumps are available and offer benefits such as eliminating oil contamination, environmental friendliness, reduced operating costs, and application flexibility. They are particularly valuable in industries where maintaining an oil-free environment is critical. Understanding the specific requirements of the application and consulting with pump manufacturers can help in selecting the appropriate type of pump for the desired operation.

How Does a Rotary Vane Pump Work?

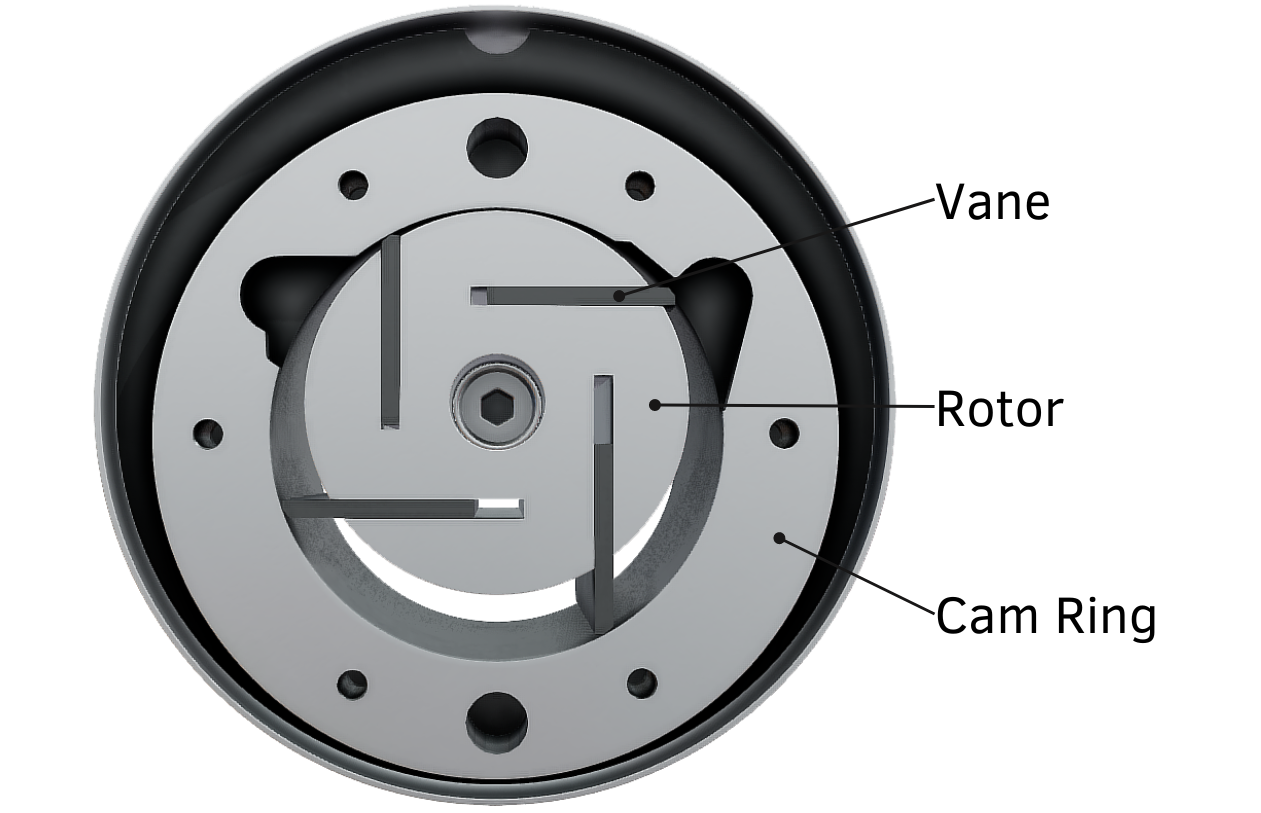

A rotary vane pump is a type of positive displacement pump commonly used for creating vacuum or low-pressure environments. Here’s a detailed explanation of how a rotary vane pump works:

– Basic Principle: A rotary vane pump operates based on the principle of positive displacement. It uses a rotating mechanism with sliding vanes to create a continuous pumping action.

– Construction: A typical rotary vane pump consists of several key components:

– Rotor: The rotor is the central rotating element of the pump. It is typically offset from the center of the pump chamber and is connected to a drive mechanism, such as an electric motor.

– Vanes: The vanes are sliding elements that are inserted into radial slots in the rotor. They can be made of various materials, such as carbon, graphite, or synthetic materials, and are in constant contact with the pump chamber walls.

– Stator: The stator is the stationary part of the pump. It forms the pump chamber and is typically cylindrical in shape with an eccentric bore that accommodates the rotor.

– Inlet and Outlet Ports: The pump has separate inlet and outlet ports. The inlet allows the entry of gas or fluid into the pump, while the outlet facilitates the discharge of the pumped medium.

– Operation:

1. Starting Position: Initially, the rotor is positioned eccentrically within the stator, creating spaces, or cells, between the rotor vanes and the stator walls.

2. Intake Stroke: As the rotor rotates, one vane enters the intake port. This creates an expanding cell, leading to a decrease in pressure within the cell. This pressure drop causes gas or fluid to enter the pump through the inlet port and fill the expanding cell.

3. Compression Stroke: As the rotor continues to rotate, the vane moves along the stator wall, reducing the size of the cell. This compression action compresses the gas or fluid within the cell, increasing its pressure.

4. Discharge Stroke: The compressed gas or fluid is then pushed towards the outlet port as the vane moves further along the stator wall. This leads to the expulsion of the medium from the pump through the outlet port.

5. Repeat Process: The above steps are repeated continuously as the rotor continues to rotate, creating a continuous pumping action.

– Sealing and Lubrication: To ensure efficient operation and prevent leakage, rotary vane pumps require proper sealing and lubrication. The vanes slide against the stator walls, forming a seal to minimize backflow and leakage. Often, a small amount of oil or lubricant is introduced into the pump chamber to provide lubrication and maintain the seal between the vanes and the stator walls.

– Applications: Rotary vane pumps are commonly used in a variety of applications, including HVAC systems, vacuum packaging, laboratory equipment, automotive industry, and industrial processes that require vacuum or low-pressure conditions.

– It’s important to note that the performance of a rotary vane pump can be influenced by factors such as the speed of rotation, the number and dimensions of vanes, the quality of sealing, and the type of lubrication used.

In summary, a rotary vane pump operates based on the principle of positive displacement. It utilizes a rotating rotor with sliding vanes inside a stationary stator to create a continuous pumping action. The pump’s design allows for the intake, compression, and discharge of gas or fluid, making it suitable for various applications requiring vacuum or low-pressure environments.

editor by CX 2024-03-28

by

Tags:

Leave a Reply