Product Description

Product Parameters

| Model | VRD-4 | VRD-8 | VRD-16 | VRD-24 | VRD-30 | VRD-48 | VRD-65 | VRD-90 | |

| Pumping Speed | 50HZ m3/h(L/S) | 4(1.1) | 8(2.2) | 16(4.4) | 24(6.6) | 30(8.3) | 48(13.3) | 65(18) | 85(23.6) |

| 60HZ m3/h(L/S) | 4.8(1.3 | 9.6(2.6) | 19.2(5.2) | 28.8(7.9) | 36(9.9) | 57.6(16) | 78(21.6) | 102(28.3) | |

| Ultimate Partial Pressure Gas Ballast Close(Pa) | 5×10-2 | 5×10-2 | 4×10-2 | 4×10-2 | 4×10-2 | 4×10-2 | 4×10-2 | 4×10-2 | |

| Ultimate Total Pressure Gas Ballast Close(Pa) | 5×10-1 | 5×10-1 | 4×10-1 | 4×10-1 | 4×10-1 | 4×10-1 | 4×10-1 | 4×10-1 | |

| Ultimate Total Pressure Gas Ballast Open(Pa) | 10 | 10 | 8×10-1 | 8×10-1 | 8×10-1 | 1.5 | 1.5 | 1.5 | |

| Power Supply | Single/3 phase | 3 phase | |||||||

| Power(kw) | 0.4/0.37 | 0.4/0.37 | 0.55 | 0.75 | 1.1 | 1.5 | 2.2 | 3 | |

| Level of Protection | IP44 | IP44 | IP44 | IP44 | IP44 | IP44 | IP44 | IP44 | |

| Air Intake/Exhaust Port | KF16/25 | KF16/25 | KF25 | KF25/40 | KF25/40 | KF40 | KF40 | KF40 | |

| Oil Mass(L) | 0.6-1.0 | 0.6-1.0 | 0.9-1.5 | 1.3-2.0 | 1.3-2.0 | 3.3-4.5 | 3.3-4.5 | 3.3-4.5 | |

| Motor Speed 50/60Hz(rpm) | 1440/1720 | 1440/1720 | 1440/1720 | 1440/1720 | 1440/1720 | 1440/1720 | 1440/1720 | 1440/1720 | |

| Ambient Temperature(ºC) | 10-40 | 10-40 | 10-40 | 10-40 | 10-40 | 10-40 | 10-40 | 10-40 | |

| Noise Level(dB) | ≤52 | ≤52 | ≤58 | ≤58 | ≤58 | ≤62 | ≤62 | ≤65 | |

| Weight(kg) | 19 | 21 | 30 | 35 | 43 | 62 | 65 | 65 | |

| Size(L*W*H mm) | 440*144*217 | 440*144*217 | 530*188*272 | 567*188*272 | 567*188*272 | 730*234*358 | 730*234*358 | 730*234*358 | |

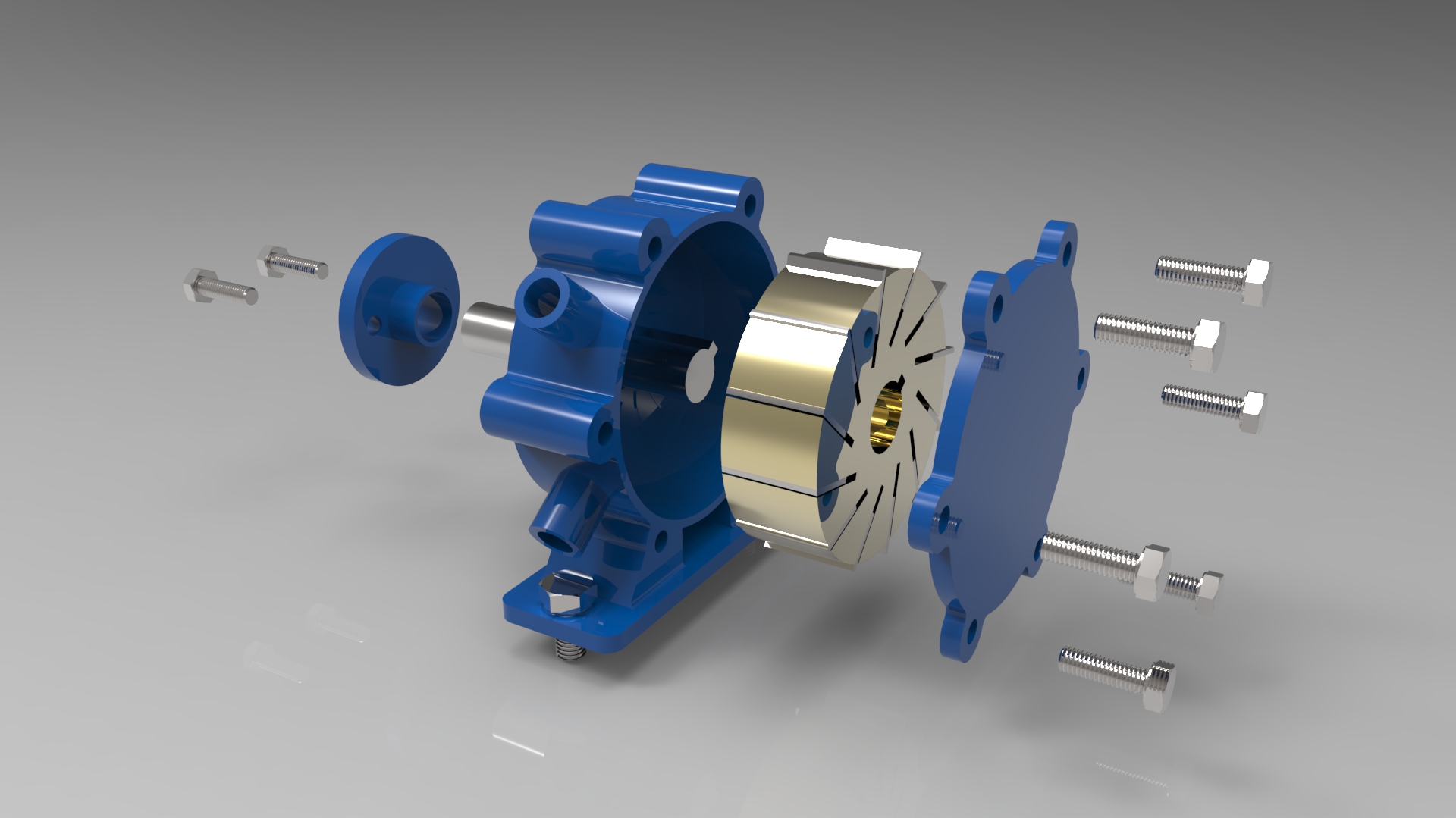

Product Description

“BOTH” VRD series pumps are designed for reliable long time continuous operation, they will take your equipment’s vacuum down to 0.3 CHINAMFG in minutes. Comes standard with all necessary fittings and a high capacity exhaust oil mist filter which also returns trapped pump oil back to the pump and makes the pump quieter to run. Multi-level gas ballast is designed to allow purposefully pull a less deep and slower vacuum by opening the gas ballast, allowing dry air to go directly into the pump and diluting the vacuum pull, and it also helps keep moisture, solvent, and other contaminants from getting stuck in the pump, and instead passing through to the exhaust. It is important to note that pumps should always be ran in a well ventilated area

· Tow-Shift adjustable gas ballast valve satisfies different requirements of condensable vapor(such as water vapor) to be exhausted

· Out of pump in different processes. Dual protection of oil anti-sucking back ensures vacuum system from oil pollution when pump

· Stops running and needs to be easily restarted. Forced oil circulation system consisted of oil pump and constant pressure oil supply mechanism ensures stable running of the pump.

· Less components are used, easy to maintain and repair

Application

· Rotary Vane Vacuum Pump corollary use with freezer dryer to reach vacuum state, it’s an essential corollary equipment in medicine CHINAMFG drying, biology, food industry and agricultural products deep processing

· Rotary Vane Vacuum Pump corollary use with vacuum drying oven for maintaining vacuum state inside the oven, they mainly applies in powder drying and baking in vacuum condition

Company Profile

Packaging & Shipping

FAQ

Q1. What is your products range?

• Industry water chiller, recirculating cooling chiller, rotary evaporator, alcohol recovery equipment, short path distillation kit, glass molecular distillation equipment, falling film evaporator, jacketed glass reactor and other lab equipment.

Q2. Are you trading company or manufacturer?

• We are professional manufacture of lab equipment and we have our own factory.

Q3. Do you provide samples? Is it free?

• Yes, we could offer the sample. Considering the high value of our products, the sample is not free, but we will give you our best price including shipping cost.

Q4. Do you have warranty?

• Yes, we offer 1 year warranty for the spare part.

Q5. How long is your delivery time?

• Generally it is within 7 working days after receiving the payment if the goods are in stock. Or it is 15 working days if thegoods are not in stock, depending on order quantity.

Q6. What is your terms of payment?

• Payment≤15,000USD, 100% in advance. Payment≥15,000USD, 70% T/T in advance, balance before shipment.

(If you are concerned about payment security for the first order, we advise you can place Trade Assurance Order via Alibaba. you will get 100% payment refund if we can’t meet agreed delivery time.)

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Online Service Support |

|---|---|

| Warranty: | 2 Year |

| Oil or Not: | Oil |

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How Does the Cost of Rotary Vane Pumps Compare to Other Types?

The cost of rotary vane pumps can vary depending on factors such as pump size, design, construction materials, manufacturer, and specific application requirements. Here’s a detailed explanation of how the cost of rotary vane pumps compares to other types:

– Initial Cost: In terms of initial purchase cost, rotary vane pumps are generally considered to be more affordable compared to certain high-end pump technologies such as centrifugal pumps or positive displacement pumps with specialized designs. Rotary vane pumps are available in a wide range of sizes and configurations, allowing for cost-effective options that suit various application needs.

– Maintenance and Operating Costs: When considering the total cost of ownership, including maintenance and operating expenses, rotary vane pumps typically offer advantages. These pumps are known for their simple design, which often translates into lower maintenance requirements and costs. They generally have fewer components and straightforward maintenance procedures, making them relatively easy to service and repair. Additionally, rotary vane pumps are often energy-efficient, contributing to lower operating costs over the pump’s lifespan.

– Efficiency and Energy Consumption: Rotary vane pumps generally have lower energy consumption compared to certain other pump types, such as older reciprocating pumps or some types of diaphragm pumps. The efficient design and operation of rotary vane pumps can result in reduced energy costs, especially when coupled with appropriate motor selection and control strategies.

– Longevity and Durability: Rotary vane pumps are known for their durability and longevity, which can contribute to cost savings over time. With proper maintenance, these pumps can provide reliable performance for extended periods, reducing the need for frequent replacements. The robust construction and use of high-quality materials in rotary vane pumps enhance their resistance to wear and tear, extending their operational lifespan.

– Application-Specific Costs: The suitability and cost-effectiveness of rotary vane pumps compared to other types can vary depending on the specific application requirements. While rotary vane pumps are versatile and widely used, there may be cases where other pump technologies, such as centrifugal pumps for high-flow applications or specialized positive displacement pumps for specific fluids, offer better performance or cost advantages. It’s essential to evaluate the specific needs of the application and consider factors such as flow rate, pressure requirements, chemical compatibility, and system efficiency when comparing costs.

It’s important to note that the cost comparison between rotary vane pumps and other pump types is not universal and can vary significantly based on factors mentioned earlier. Additionally, market conditions, availability, and specific manufacturer pricing policies can influence the cost differentials between pump types.

When selecting a pump, it is advisable to consult with pump manufacturers, distributors, or industry experts to assess the overall costs and benefits associated with different pump types. They can provide insights into the upfront costs, maintenance requirements, energy efficiency, and long-term value of various pump options, helping to determine the most cost-effective solution for a specific application.

In summary, while rotary vane pumps generally offer competitive initial costs, lower maintenance and operating expenses, and good durability, the cost comparison with other pump types depends on multiple factors and the specific application requirements.

What Are the Typical Applications of Rotary Vane Pumps?

Rotary vane pumps find application in various industries and sectors due to their versatility and reliable performance. Here’s a detailed explanation of the typical applications of rotary vane pumps:

– Industrial Manufacturing: Rotary vane pumps are commonly used in industrial manufacturing processes. They are employed for tasks such as vacuum packaging, vacuum drying, vacuum distillation, and vacuum filtration. The pumps assist in creating and maintaining the necessary vacuum levels for these manufacturing operations.

– HVAC Systems: Rotary vane pumps play a crucial role in heating, ventilation, and air conditioning (HVAC) systems. They are utilized for tasks such as evacuating air and moisture from refrigeration and air conditioning systems during installation or maintenance. Rotary vane pumps ensure proper system performance and prevent issues like refrigerant contamination.

– Laboratory and Scientific Research: Rotary vane pumps are widely used in laboratory settings and scientific research facilities. They are employed in applications such as vacuum ovens, freeze drying, sample preparation, and vacuum distillation. Rotary vane pumps provide the necessary vacuum conditions for experiments, sample processing, and equipment operation.

– Medical and Healthcare: Rotary vane pumps find application in the medical and healthcare industry. They are used in medical devices such as vacuum suction units, blood analyzers, and laboratory equipment. Rotary vane pumps assist in creating a vacuum for various medical procedures, diagnostics, and research activities.

– Automotive: Rotary vane pumps are utilized in automotive systems, particularly in vehicles with diesel engines. They are commonly employed as vacuum pumps for brake boosters, which enhance braking performance. Rotary vane pumps ensure reliable vacuum supply for effective braking, contributing to vehicle safety.

– Printing and Packaging: Rotary vane pumps are employed in printing and packaging industries. They are used for tasks such as vacuum hold-down in printing presses and vacuum packaging of products. Rotary vane pumps facilitate the precise handling of paper, cardboard, and other materials during printing and packaging processes.

– Food and Beverage Processing: Rotary vane pumps find application in the food and beverage industry. They are utilized for tasks such as vacuum packaging of perishable products, vacuum degassing of liquids, and vacuum filling of bottles or containers. Rotary vane pumps contribute to extending the shelf life of food products and ensuring their quality.

– Environmental Applications: Rotary vane pumps are utilized in environmental applications such as air sampling and monitoring equipment. They assist in creating a vacuum for sampling air pollutants, analyzing air quality, and conducting environmental research.

– Semiconductor Manufacturing: Although rotary vane pumps may not be suitable for ultra-high vacuum applications in semiconductor manufacturing, they still find utility in certain stages of the process. They are often used for tasks such as load-lock operations, wafer handling, and general vacuum needs that do not require extremely low pressures.

– Other Applications: Rotary vane pumps have additional applications in areas such as power generation, oil and gas, chemical processing, pharmaceutical production, and wastewater treatment. They are employed for various tasks involving vacuum generation, fluid handling, and system evacuation.

In summary, rotary vane pumps have diverse applications across industries, including industrial manufacturing, HVAC systems, laboratory research, medical and healthcare, automotive, printing and packaging, food and beverage processing, environmental monitoring, and more. Their reliable performance, versatility, and ability to create vacuum make them valuable in numerous applications and processes.

editor by CX 2024-04-15

by

Tags:

Leave a Reply