Product Description

Product Description

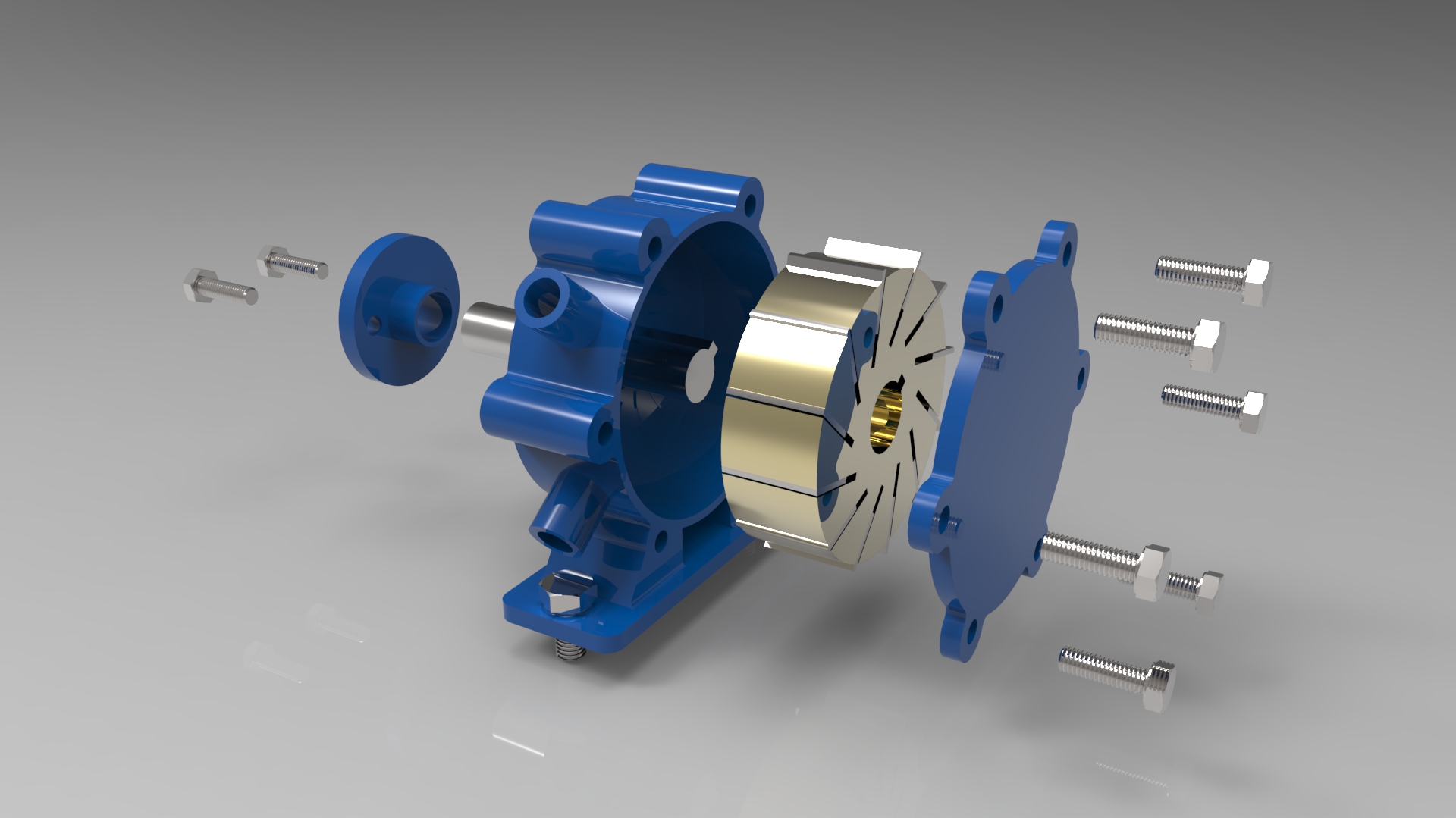

2XZ-4 rotary vane vacuum pump is double stage high speed oil sealed rotary vane vacuum pump (in the following called “the pump” for short).

Its pumping principle is as same as that of 2X type pump .Rotors are eccentrically mounted within the cylindrical housing of the stators and vanes are fitted freely inside the respective slots of the rotor. When the rotor rotates at high speed, vanes in the rotor slot are urged outwards by centrifugal force as well as by spring force so as to keep close contact at their tips with the stator wall throughout rotation.

Thus the inlet port and outlet port on the stator are separated by them. The volume of the space leading to the inlet port expands progressively and periodically with gas filling the space through inlet pipe, meanwhile the volume of the space leading to the outlet port diminishes progressively and periodically to compress the gas previously sucked .By means of gas pressure and oil pressure exhaust valve on the outlet port is opened to expel gas out of the pump through the valve, then vacuum is obtained at the intake side of the pump .

Double stage pump is the arrangement of 2 CHINAMFG pumps in series .When the intake pressure is higher, both stages of the pump may exhaust simultaneously ,while at lower suction pressure gas is first expelled out from first stage to second stage ,then from second stage exhausts to the open air .

Product Application

1. The pump is 1 of the basic equipment to exhaust a sealed vessel. It can be used either independently as main and can also be served as for pump for booster pump diffusion pump and molecular pump or as holding pump for a vacuum system and as a pre-pumping for different kinds of the pumps. So that is can be applied in electro-vacuum industries, vacuum flask manufacturing, vacuum welding and as an accessory to those fine gauges or CHINAMFG where vacuum is required .It is more suitable for laboratory use because of its small size ,less weight and quiet operation.

2.The pump is allowed to work continuously for many hours at a stretch under atmospheric temperature of 5ºC-40ºC and intake pressure below 1230pa.While the pumped gas containing moisture of a relative humidity of more than 90% gas-ballast valve should be open.

3. Whit the inlet port widely opened to atmosphere the pump is not allowed to work more than 1 minute.

4.The pump is not suitable for pumping over-oxidized, poison, explosive and corrosive gas as well as gases which react chemically with the pump oil contain particles of dust.

Product Details

Q: What kind of gas is not suitable for 2XZ-2 of rotary vane vacuum pump to pump out?

A: Corrosive to the metal, the chemical reaction to the pump oil, containing particles of dust, high oxygen content, explosive, and toxic gases.

Q: The working environment of 2XZ-2 refrigeration vacuum pump?

A: 5ºC-40ºC, the relative temperature is not higher than 90%. When the inlet pressure is less than 1333pa, it is allowed to work continuously for a long time.

Q: What is the payment terms?

T/T, Paypal, Western Union, Ali credit insurance, L/C etc

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | 1 Year |

|---|---|

| Warranty: | 1 Year |

| Oil or Not: | Oil |

| Structure: | Rotary Vacuum Pump |

| Exhauster Method: | Entrapment Vacuum Pump |

| Vacuum Degree: | High Vacuum |

| Samples: |

US$ 260/Piece

1 Piece(Min.Order) | |

|---|

What Is the Energy Efficiency of Rotary Vane Pumps?

The energy efficiency of rotary vane pumps can vary depending on several factors, including the design of the pump, operating conditions, and specific application requirements. Here’s a detailed explanation of the energy efficiency considerations for rotary vane pumps:

– Design Efficiency: The design of the rotary vane pump can significantly impact its energy efficiency. Modern rotary vane pumps are designed with efficiency in mind, incorporating features such as optimized rotor profiles, improved sealing mechanisms, and reduced internal leakage. These design enhancements aim to minimize energy losses and maximize the pump’s overall efficiency.

– Motor Efficiency: The motor driving the rotary vane pump plays a crucial role in its energy efficiency. High-efficiency motors, such as those meeting premium efficiency standards (e.g., NEMA Premium Efficiency or IE3), can contribute to the overall energy efficiency of the pump system. Using motors with appropriate power ratings and matching the motor size to the pump’s requirements can help optimize energy consumption.

– Operating Point: The operating point at which the rotary vane pump operates can impact its energy efficiency. Pumps often have an optimum operating range where they achieve the highest efficiency. Operating the pump within this range can help minimize unnecessary energy consumption. It’s important to consider the system requirements and select a pump that can operate efficiently under the expected operating conditions.

– Control and Automation: Implementing effective control and automation strategies can enhance the energy efficiency of rotary vane pump systems. Variable frequency drives (VFDs) or speed control mechanisms can adjust the pump’s speed or output to match the required flow rate, reducing energy wastage. Additionally, incorporating sensors and control algorithms that optimize pump operation based on demand can further improve energy efficiency.

– System Design and Integration: The overall system design and integration can influence the energy efficiency of rotary vane pumps. Proper sizing of the pump based on the system requirements, minimizing pressure losses in the piping network, and optimizing the layout of the system components can all contribute to improved energy efficiency. Considering the system as a whole and implementing energy-saving practices can result in significant energy savings.

– Maintenance and Performance Monitoring: Regular maintenance and performance monitoring are essential for maintaining the energy efficiency of rotary vane pumps. Ensuring proper lubrication, monitoring for leaks or wear, and addressing any performance issues promptly can prevent energy losses due to degraded pump performance. Periodic performance assessments and efficiency measurements can help identify opportunities for optimization and energy-saving initiatives.

It’s important to note that the energy efficiency of rotary vane pumps can vary among different pump models and manufacturers. When selecting a rotary vane pump, it is advisable to review the manufacturer’s specifications, efficiency data, and performance curves to evaluate the pump’s energy efficiency characteristics.

Overall, by considering design efficiency, motor efficiency, operating point, control strategies, system design, and maintenance practices, it is possible to enhance the energy efficiency of rotary vane pumps and reduce energy consumption in various applications.

What Are the Typical Applications of Rotary Vane Pumps?

Rotary vane pumps find application in various industries and sectors due to their versatility and reliable performance. Here’s a detailed explanation of the typical applications of rotary vane pumps:

– Industrial Manufacturing: Rotary vane pumps are commonly used in industrial manufacturing processes. They are employed for tasks such as vacuum packaging, vacuum drying, vacuum distillation, and vacuum filtration. The pumps assist in creating and maintaining the necessary vacuum levels for these manufacturing operations.

– HVAC Systems: Rotary vane pumps play a crucial role in heating, ventilation, and air conditioning (HVAC) systems. They are utilized for tasks such as evacuating air and moisture from refrigeration and air conditioning systems during installation or maintenance. Rotary vane pumps ensure proper system performance and prevent issues like refrigerant contamination.

– Laboratory and Scientific Research: Rotary vane pumps are widely used in laboratory settings and scientific research facilities. They are employed in applications such as vacuum ovens, freeze drying, sample preparation, and vacuum distillation. Rotary vane pumps provide the necessary vacuum conditions for experiments, sample processing, and equipment operation.

– Medical and Healthcare: Rotary vane pumps find application in the medical and healthcare industry. They are used in medical devices such as vacuum suction units, blood analyzers, and laboratory equipment. Rotary vane pumps assist in creating a vacuum for various medical procedures, diagnostics, and research activities.

– Automotive: Rotary vane pumps are utilized in automotive systems, particularly in vehicles with diesel engines. They are commonly employed as vacuum pumps for brake boosters, which enhance braking performance. Rotary vane pumps ensure reliable vacuum supply for effective braking, contributing to vehicle safety.

– Printing and Packaging: Rotary vane pumps are employed in printing and packaging industries. They are used for tasks such as vacuum hold-down in printing presses and vacuum packaging of products. Rotary vane pumps facilitate the precise handling of paper, cardboard, and other materials during printing and packaging processes.

– Food and Beverage Processing: Rotary vane pumps find application in the food and beverage industry. They are utilized for tasks such as vacuum packaging of perishable products, vacuum degassing of liquids, and vacuum filling of bottles or containers. Rotary vane pumps contribute to extending the shelf life of food products and ensuring their quality.

– Environmental Applications: Rotary vane pumps are utilized in environmental applications such as air sampling and monitoring equipment. They assist in creating a vacuum for sampling air pollutants, analyzing air quality, and conducting environmental research.

– Semiconductor Manufacturing: Although rotary vane pumps may not be suitable for ultra-high vacuum applications in semiconductor manufacturing, they still find utility in certain stages of the process. They are often used for tasks such as load-lock operations, wafer handling, and general vacuum needs that do not require extremely low pressures.

– Other Applications: Rotary vane pumps have additional applications in areas such as power generation, oil and gas, chemical processing, pharmaceutical production, and wastewater treatment. They are employed for various tasks involving vacuum generation, fluid handling, and system evacuation.

In summary, rotary vane pumps have diverse applications across industries, including industrial manufacturing, HVAC systems, laboratory research, medical and healthcare, automotive, printing and packaging, food and beverage processing, environmental monitoring, and more. Their reliable performance, versatility, and ability to create vacuum make them valuable in numerous applications and processes.

editor by Dream 2024-04-22

by

Tags:

Leave a Reply