Product Description

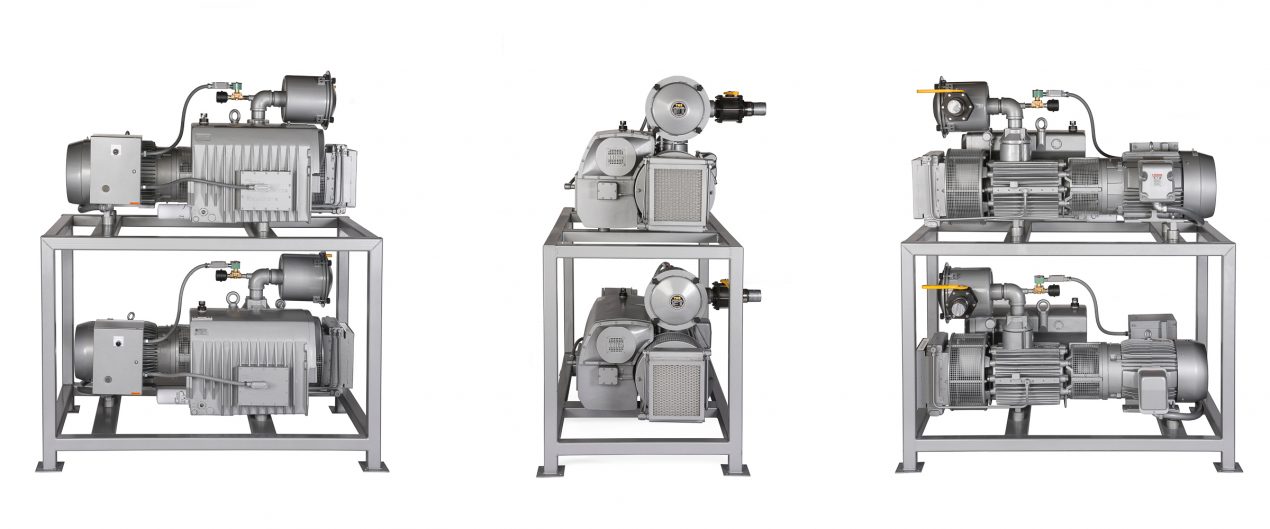

XD series vacuum pump

XD series vacuum pump is a single-stage rotary vane oil-sealed vacuum pump, which is 1 of main low and medium vacuum equipments. It can be used separately and be as forepump of vacuum pump, mechanical booster pump, and turbo molecular pump.

XD series vacuum pumps are available for low and medium vacuum fields, which are mainly used for pumping air and other dry gases rather than corrosive, toxic, flammable and explosive gases. Furthermore, they cannot pump the gases containing tiny particles or dust and cannot transport other small objects.

XD series vacuum pumps can work for long term in the well-ventilated room with ambient temperature of 5-30 ºC and with humidity ≤80%. In addition to the above applications, the XD series vacuum pumps can be available other applications, such as:

1. To increase the amount of the pumping gas and to improve the vacuum degree, please combine with Roots pumps to form a unit for this.

2. If pumping moist air or condensable gas, the condenser can be installed before the vacuum pump and the gas ballast valve is installed on the vacuum pump.

3. If pumping the gases containing dust particles, the dust filters can be installed in front of the vacuum pump.

4. If pumping the corrosive gases, the corrosion-proof gas filter can be installed in front of the vacuum pump.

|

Parameters Model |

XD-571 | XD-040 | XD-063 | XD-100 | XD-160 | XD-202 | XD-250 | XD-302 |

|

Pumping rate (m³/h) |

20 | 40 | 63 | 100 | 160 | 202 | 250 | 302 |

|

PressureLimit (mbar) |

0.1~0.5 | 0.1~0.5 | 0.1~0.5 | 0.1~0.5 | 0.5 | 0.1 | 0.1 | 0.1 |

|

MotorPower (KW) |

0.75 (single phase0.9Kw | 1.5 | 2.2 | 3 | 4.5 | 4.5 | 5.5 | 7.5 |

|

Motor Speed (r/min) |

2880 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 |

|

Noise (db) |

≤62 | ≤65 | ≤65 | ≤67 | ≤70 | ≤72 | ≤73 | ≤75 |

|

Allowable steam pressure (mbar) |

40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 |

|

Working water steam (Kg/h) |

0.3 | 0.3 | 1 | 1.6 | 2.5 | 4 | 4.5 | 5 |

|

Working temperature (ºC) |

82 | 80 | 80 | 84 | 95 | 95 | 81 | 83 |

|

Oil volume

(L) |

0.5 | 1 | 2 | 2 | 5 | 5 | 7 | 7 |

|

Weight

(kg) |

13 | 40 | 65 | 78 | 140 | 140 | 185 | 201 |

|

Air intake thread |

Rp3/4″ | Rp11/4″ | Rp11/4″ | Rp11/4″ | Rp2″ | Rp2″ | Rp2″ | Rp2″ |

|

Overall dimensions L*W*H |

650*300*280 | 650*300*280 | 650*430*295 | 720*430*295 | 85*50.5*44 | 85*50.5*44 | 98*56*44 | 101*56*44 |

Product’s Application

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Warranty: | One Year |

|---|---|

| Oil or Not: | Oil |

| Structure: | Singel Stage |

| Exhauster Method: | Pumping Air |

| Vacuum Degree: | High Vacuum |

| Work Function: | Mainsuction Pump |

| Customization: |

Available

|

|

|---|

Are There Oil-Free Rotary Vane Pump Options Available?

Yes, there are oil-free rotary vane pump options available in the market. These pumps are designed to operate without the need for lubricating oil, offering certain advantages and applications where oil contamination is a concern. Here’s a detailed explanation:

– Dry Vane Technology: Oil-free rotary vane pumps, also known as dry vane pumps, utilize specialized dry vane technology. Instead of relying on lubricating oil to create a seal and reduce friction, these pumps use self-lubricating materials and innovative design features to achieve efficient operation without oil.

– Reduced Contamination Risk: One of the primary advantages of oil-free rotary vane pumps is that they eliminate the risk of oil contamination. In certain applications, such as in the food and beverage industry, pharmaceutical production, or cleanroom environments, maintaining a completely oil-free and contaminant-free operation is critical. Oil-free rotary vane pumps address these requirements and ensure the purity and integrity of the process or product being handled.

– Environmental Friendliness: Oil-free rotary vane pumps are considered more environmentally friendly compared to their oil-lubricated counterparts. The elimination of oil lubrication means there is no risk of oil leaks or spills, reducing the potential impact on the environment. These pumps also eliminate the need for oil changes and disposal, resulting in lower maintenance and disposal costs.

– Lower Operating Costs: Oil-free rotary vane pumps can offer cost advantages in terms of operating expenses. Since they do not require oil lubrication, there is no need to purchase, monitor, or replace oil. This can result in savings over the pump’s lifetime. Additionally, oil-free pumps often have lower maintenance requirements, as there is no need to monitor oil levels, change oil, or replace oil filters.

– Application Flexibility: Oil-free rotary vane pumps are suitable for a range of applications where oil contamination must be avoided. They find application in industries such as food and beverage, pharmaceuticals, medical devices, laboratory research, electronics manufacturing, and other sensitive environments. These pumps can handle both gas and some liquid applications, providing versatility in various processes.

– Considerations: While oil-free rotary vane pumps offer several advantages, it’s important to consider certain factors when choosing these pumps. They may have slightly different operating characteristics compared to oil-lubricated pumps, such as lower ultimate vacuum levels or reduced performance in high-pressure applications. It’s crucial to assess the specific requirements of the application and consult the manufacturer’s specifications to ensure the chosen oil-free rotary vane pump meets the desired performance criteria.

– Alternative Technologies: In cases where oil-free rotary vane pumps may not be suitable, alternative technologies such as dry screw pumps or dry claw pumps can be considered. These pumps also offer oil-free operation and have their own unique advantages and applications.

In summary, oil-free rotary vane pumps are available and offer benefits such as eliminating oil contamination, environmental friendliness, reduced operating costs, and application flexibility. They are particularly valuable in industries where maintaining an oil-free environment is critical. Understanding the specific requirements of the application and consulting with pump manufacturers can help in selecting the appropriate type of pump for the desired operation.

How Does a Rotary Vane Pump Work?

A rotary vane pump is a type of positive displacement pump commonly used for creating vacuum or low-pressure environments. Here’s a detailed explanation of how a rotary vane pump works:

– Basic Principle: A rotary vane pump operates based on the principle of positive displacement. It uses a rotating mechanism with sliding vanes to create a continuous pumping action.

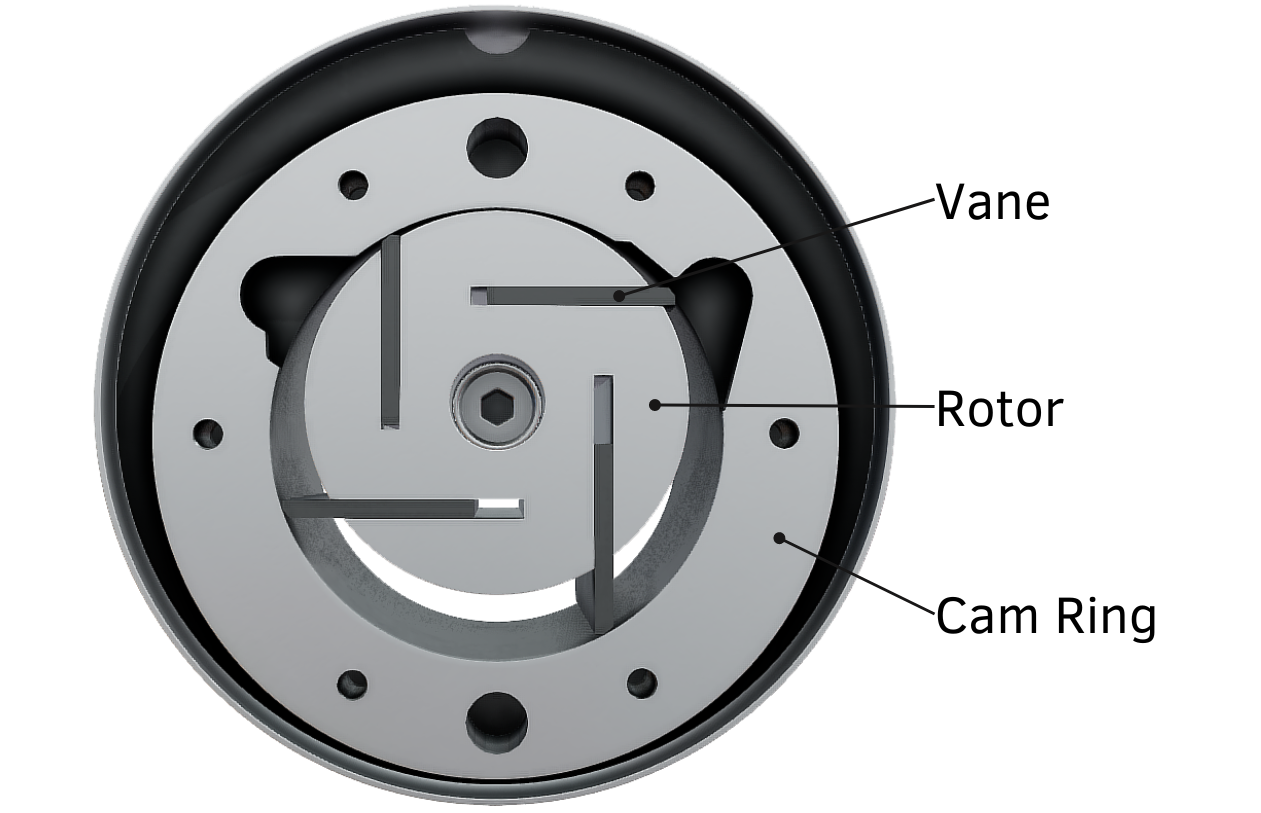

– Construction: A typical rotary vane pump consists of several key components:

– Rotor: The rotor is the central rotating element of the pump. It is typically offset from the center of the pump chamber and is connected to a drive mechanism, such as an electric motor.

– Vanes: The vanes are sliding elements that are inserted into radial slots in the rotor. They can be made of various materials, such as carbon, graphite, or synthetic materials, and are in constant contact with the pump chamber walls.

– Stator: The stator is the stationary part of the pump. It forms the pump chamber and is typically cylindrical in shape with an eccentric bore that accommodates the rotor.

– Inlet and Outlet Ports: The pump has separate inlet and outlet ports. The inlet allows the entry of gas or fluid into the pump, while the outlet facilitates the discharge of the pumped medium.

– Operation:

1. Starting Position: Initially, the rotor is positioned eccentrically within the stator, creating spaces, or cells, between the rotor vanes and the stator walls.

2. Intake Stroke: As the rotor rotates, one vane enters the intake port. This creates an expanding cell, leading to a decrease in pressure within the cell. This pressure drop causes gas or fluid to enter the pump through the inlet port and fill the expanding cell.

3. Compression Stroke: As the rotor continues to rotate, the vane moves along the stator wall, reducing the size of the cell. This compression action compresses the gas or fluid within the cell, increasing its pressure.

4. Discharge Stroke: The compressed gas or fluid is then pushed towards the outlet port as the vane moves further along the stator wall. This leads to the expulsion of the medium from the pump through the outlet port.

5. Repeat Process: The above steps are repeated continuously as the rotor continues to rotate, creating a continuous pumping action.

– Sealing and Lubrication: To ensure efficient operation and prevent leakage, rotary vane pumps require proper sealing and lubrication. The vanes slide against the stator walls, forming a seal to minimize backflow and leakage. Often, a small amount of oil or lubricant is introduced into the pump chamber to provide lubrication and maintain the seal between the vanes and the stator walls.

– Applications: Rotary vane pumps are commonly used in a variety of applications, including HVAC systems, vacuum packaging, laboratory equipment, automotive industry, and industrial processes that require vacuum or low-pressure conditions.

– It’s important to note that the performance of a rotary vane pump can be influenced by factors such as the speed of rotation, the number and dimensions of vanes, the quality of sealing, and the type of lubrication used.

In summary, a rotary vane pump operates based on the principle of positive displacement. It utilizes a rotating rotor with sliding vanes inside a stationary stator to create a continuous pumping action. The pump’s design allows for the intake, compression, and discharge of gas or fluid, making it suitable for various applications requiring vacuum or low-pressure environments.

editor by Dream 2024-04-26

Leave a Reply