Product Description

Product Description

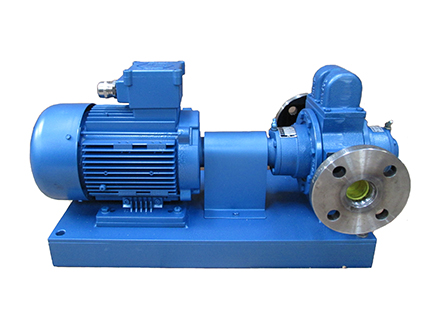

ZYBW Series Dry Running Vacuum / Pressure Combined Pump

Introducing the ZYBW Series Dry Running Vacuum / Pressure Combined Pump, a high-performance solution brought to you by HangZhou Mingkai Electromechanical Co., Ltd. This pump, manufactured with advanced German technology and standards, offers a unique combination of vacuum suction and compressed air exhaust.

Designed for ease of use and maintenance, this pump ensures a clean and oil-free exhaust, making it ideal for a wide range of industries. From printing and packaging to cigarette making and dust catching, this pump is a versatile choice. It is also suitable for applications in porcelain, ship’s dirt draining, and heat treatment.

With its oil-free operation and rotary vacuum pump structure, this pump guarantees efficient performance and a high level of vacuum. Its dry running vane design eliminates the need for oil, reducing maintenance requirements and ensuring a longer lifespan.

Whether you need a vacuum pump for a wood door making machine, a vacuum table, or a CNC router, this pump is the perfect choice. Its carbon vane technology and oil-less sliding vane design make it a reliable and efficient solution for all your vacuum needs.

Experience the benefits of the ZYBW Series Dry Running Vacuum / Pressure Combined Pump. Order yours today and enjoy its exceptional performance and reliability.

Features At A Glance

ZYBW Series Dry Running Vacuum / Pressure Combined Pump

Introducing the ZYBW Series Dry Running Vacuum / Pressure Combined Pump from HangZhou Mingkai Electromechanical Co., Ltd. This high-performance carbon vane vacuum pump is designed to provide a calm and soothing experience for your vacuuming needs.

- Almost Completely Maintenance-Free: With its advanced design, this pump requires minimal maintenance, allowing you to focus on other tasks.

- Wide Range of Performance: Whether you need to create a strong vacuum or generate pressure, this pump offers a versatile range of performance to meet your specific requirements.

- Robust Yet Lightweight: Built with durability in mind, this pump is robust enough to withstand demanding applications while remaining lightweight for easy handling.

- Reliability – Built to Last: Crafted with precision and high-quality materials, this pump is built to last, ensuring long-term reliability and peace of mind.

- 50/60 Hz Voltage Range Motors: This pump is equipped with motors that can operate efficiently within a wide voltage range, providing flexibility and compatibility.

- Low Level of Noise: Enjoy a quiet and serene environment with this pump’s low noise level, allowing you to work or relax without disturbance.

- Easy Installation: Setting up this pump is a breeze, thanks to its user-friendly design and straightforward installation process.

- No Vibration, Complete Dynamic Stability: Experience smooth and stable operation with this pump, as it eliminates vibrations and ensures complete dynamic stability.

Whether you need a vacuum pump for a CNC router, wood door making machine, or vacuum table, this ZYBW Series Dry Running Vacuum / Pressure Combined Pump is the perfect choice. Its oil-free and rotary vacuum pump structure guarantees a high level of vacuum, making it suitable for various applications. Don’t compromise on performance and reliability – choose the ZYBW Series Dry Running Vacuum / Pressure Combined Pump for all your vacuuming needs.

Product Parameters

| Model | Power(kw) | Voltage(V) | Speed(rmp) | Air flow(m3/h) | Vacuum(KPa) | Pressure(KPa) | In/Outlet size | Weight(kg) | |

| ZYBW-60F | 3 | 220/380 | 1420 | 60 | 60 | 60 | 27/20/27 | 84 | |

| ZYBW-80F | 4 | 220/380 | 1420 | 80 | 60 | 60 | 33/27/33 | 94 | |

| ZYBW-100F | 5.5 | 220/380 | 1420 | 100 | 60 | 60 | 34 | 120 | |

| ZYBW-140F | 5.5/7.5 | 220/380 | 1420 | 140 | 60 | 60 | 42/27/48 | 133 | |

| ZYBW-160F | 7.5 | 220/380 | 1420 | 160 | 60 | 60 | 24.1/38.9/44.8 | 145 | |

Company Profile

Our Services

24 hours service online.

you can touch us by email, ,what’s app,telephone QQ etc

Legion Zheng (Sales Manager)

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Oil or Not: | Oil Free |

|---|---|

| Structure: | Rotary Vacuum Pump |

| Vacuum Degree: | Vacuum |

| Samples: |

US$ 995/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What Industries Commonly Rely on Rotary Vane Pumps?

Rotary vane pumps find application in various industries where their characteristics and capabilities are well-suited to meet specific requirements. Here’s a detailed explanation of the industries that commonly rely on rotary vane pumps:

– HVAC and Refrigeration: Rotary vane pumps are widely used in the heating, ventilation, air conditioning, and refrigeration industry. They are utilized for tasks such as evacuating and charging refrigerant systems, recovering refrigerants, and creating the necessary vacuum conditions for efficient operation. Rotary vane pumps provide reliable and efficient performance in HVAC and refrigeration applications.

– Automotive and Manufacturing: The automotive industry and manufacturing sector often rely on rotary vane pumps for various applications. These pumps are used for vacuum-assisted brake systems, fuel vapor recovery, vacuum molding, pick and place operations, and other tasks that require vacuum or pressure generation. Rotary vane pumps’ compact size, versatility, and ability to handle both gas and liquid applications make them suitable for diverse automotive and manufacturing processes.

– Printing and Paper: Rotary vane pumps are utilized in the printing and paper industry for tasks such as paper handling, ink transfer, and vacuum-assisted processes. These pumps provide the necessary vacuum conditions to hold paper in place during printing, enable ink circulation and transfer, and assist in paper transport. Rotary vane pumps’ reliability, efficiency, and ability to handle both dry and wet processes make them valuable in the printing and paper industry.

– Laboratory and Scientific Research: Rotary vane pumps are commonly found in laboratory and scientific research environments. They are used for applications such as vacuum filtration, degassing, rotary evaporation, and other processes requiring precise vacuum control. Rotary vane pumps’ compact design, low noise levels, and compatibility with a wide range of chemicals and solvents make them suitable for laboratory and research applications.

– Food and Beverage: In the food and beverage industry, rotary vane pumps are utilized for tasks such as vacuum packaging, liquid transfer, and product handling. These pumps provide the necessary vacuum conditions for sealing packages, transferring liquids, and maintaining product integrity. Rotary vane pumps’ ability to handle both liquid and gas applications, as well as their hygienic design options, make them suitable for food and beverage processing.

– Environmental and Analytical Instruments: Rotary vane pumps are utilized in environmental monitoring and analytical instruments. They are used for tasks such as sample collection, gas analysis, and air monitoring. These pumps provide the required vacuum conditions for sample collection and analysis, ensuring accurate and reliable results. Rotary vane pumps’ compatibility with a wide range of gases and their ability to handle varying flow rates make them valuable in environmental and analytical applications.

– Medical and Healthcare: The medical and healthcare industry relies on rotary vane pumps for various applications, including vacuum-assisted wound therapy, suction devices, and medical gas systems. These pumps provide the necessary vacuum or pressure conditions required for medical procedures and equipment. Rotary vane pumps’ reliability, compact size, and compatibility with medical gases make them essential in the medical and healthcare sector.

It’s important to note that while rotary vane pumps are commonly used in these industries, specific applications and requirements may vary. Different pump models and configurations may be chosen based on factors such as flow rate, vacuum level, chemical compatibility, and operating conditions.

In summary, rotary vane pumps are relied upon by industries such as HVAC and refrigeration, automotive and manufacturing, printing and paper, laboratory and scientific research, food and beverage, environmental and analytical instruments, and medical and healthcare. Their versatility, efficiency, and ability to handle a wide range of applications make them valuable in these sectors.

How Do You Maintain and Service a Rotary Vane Pump?

Maintaining and servicing a rotary vane pump is essential to ensure its optimal performance and prolong its operational life. Here’s a detailed explanation of the maintenance and servicing procedures for a rotary vane pump:

– Regular Inspection: Perform regular visual inspections of the pump to check for any signs of wear, leaks, or damage. Inspect the pump housing, vanes, seals, and connections. Look for any loose or worn parts that may require attention.

– Lubrication: Proper lubrication is crucial for the smooth operation of a rotary vane pump. Follow the manufacturer’s guidelines regarding the type and frequency of lubrication. Typically, the pump requires lubrication with a suitable oil or grease. Ensure that the lubrication level is adequate, and monitor the condition of the lubricant. Replace or replenish the lubricant as recommended.

– Vane Replacement: The vanes in a rotary vane pump can wear down over time and may need to be replaced periodically. Inspect the vanes regularly and look for signs of wear, such as cracks or reduced thickness. Replace the vanes if necessary, following the manufacturer’s instructions.

– Cleaning: Keep the pump and its components clean to prevent the buildup of debris or contaminants. Use a suitable cleaning agent and a soft cloth or brush to clean the pump housing, vanes, and other parts. Avoid using harsh chemicals or abrasive materials that may damage the pump surfaces.

– Filter Maintenance: If the rotary vane pump has an inlet filter, inspect and clean or replace it regularly. The filter prevents debris from entering the pump and affecting its performance. Follow the manufacturer’s recommendations for filter maintenance and replacement intervals.

– Seals and Gaskets: Check the seals and gaskets of the pump for signs of wear or leakage. Replace any damaged or worn seals to maintain proper sealing and prevent fluid or gas leaks.

– Motor and Electrical Connections: Inspect the motor and electrical connections of the pump for any loose or damaged wires. Ensure that the electrical connections are secure and free from corrosion. If any issues are found, consult a qualified technician or electrician for repairs.

– Operating Conditions: Ensure that the pump is operated within its specified operating conditions. Avoid subjecting the pump to excessive temperatures, pressures, or fluid viscosity that may exceed its capabilities. Adhere to the recommended operating parameters to prevent premature wear or damage to the pump.

– Service and Calibration: Periodically, consider having the rotary vane pump serviced and calibrated by a qualified technician. This ensures that the pump is operating at its optimal performance and accuracy. The technician can perform maintenance tasks, inspect internal components, and make any necessary adjustments or repairs.

It’s important to consult the manufacturer’s guidelines and recommendations specific to your rotary vane pump model for detailed maintenance and servicing instructions. Adhering to these guidelines and performing regular maintenance will help keep the pump in good working condition and extend its service life.

editor by Dream 2024-04-30

by

Tags:

Leave a Reply