Product Description

Product Overview

XD Series CHINAMFG Vacuum Sealer Rotary Vane Vacuum Pump

Vacuum pumps are mainly used in vacuum packaging, drying, distillation, concentration, loading and unloading, suction, blow molding and other fields.

FEATURES AT A GLANCE

Good stability Low noise operation Strong draw Prevent water mixing Long service life

1.Environmental protection function, built-in oil mist filter,clean and pollution-free exhaust

2. motor and pump coaxial direct transmission, light and small

3. Air cooling, no need of cold water, simple operation, easy maintenance

4.The air inlet is equipped with a check valve, which can prevent the pump oil from entering the vacuum system

5. small vibration, low noise, water discharge plane can be operated

6. in the limit of vacuum to atmospheric pressure range of sustainable operation

PRODUCT SPECIFICATIONS

PRODUCT CONFIGURATION

Our History:Manvac was founded in 2012. Head office located in Hongkong.Factory and export sales office located in HangZhou city, China mainland.

Our Factory:Our factory located in HangZhou, with 6000m2 area, 3 buildings for produce, half finished products stock, and finished products warehouse.

Our Product:Specializing in the production of Side Channel Blower, Radial Blower, High Speed Centrifugal Blower, Air Knives Drying System, Aeration Diffusers,And other solutions to satisfy customer requirements.

Product Application:Application: WasteWater aeration treatment, air knives drying system, fish farming, industrial vacuum and pressure system etc.

Our Certificate:CE,CCC,ROHS,NEMKO,SGS,TUV,UL

XT HangZhou HongGuang Hardwares Co., Ltd.

Legion [sales & marketing]

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | 24 Hours Service Online |

|---|---|

| Warranty: | 1year |

| Oil or Not: | Oil |

| Samples: |

US$ 1788/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What Industries Commonly Rely on Rotary Vane Pumps?

Rotary vane pumps find application in various industries where their characteristics and capabilities are well-suited to meet specific requirements. Here’s a detailed explanation of the industries that commonly rely on rotary vane pumps:

– HVAC and Refrigeration: Rotary vane pumps are widely used in the heating, ventilation, air conditioning, and refrigeration industry. They are utilized for tasks such as evacuating and charging refrigerant systems, recovering refrigerants, and creating the necessary vacuum conditions for efficient operation. Rotary vane pumps provide reliable and efficient performance in HVAC and refrigeration applications.

– Automotive and Manufacturing: The automotive industry and manufacturing sector often rely on rotary vane pumps for various applications. These pumps are used for vacuum-assisted brake systems, fuel vapor recovery, vacuum molding, pick and place operations, and other tasks that require vacuum or pressure generation. Rotary vane pumps’ compact size, versatility, and ability to handle both gas and liquid applications make them suitable for diverse automotive and manufacturing processes.

– Printing and Paper: Rotary vane pumps are utilized in the printing and paper industry for tasks such as paper handling, ink transfer, and vacuum-assisted processes. These pumps provide the necessary vacuum conditions to hold paper in place during printing, enable ink circulation and transfer, and assist in paper transport. Rotary vane pumps’ reliability, efficiency, and ability to handle both dry and wet processes make them valuable in the printing and paper industry.

– Laboratory and Scientific Research: Rotary vane pumps are commonly found in laboratory and scientific research environments. They are used for applications such as vacuum filtration, degassing, rotary evaporation, and other processes requiring precise vacuum control. Rotary vane pumps’ compact design, low noise levels, and compatibility with a wide range of chemicals and solvents make them suitable for laboratory and research applications.

– Food and Beverage: In the food and beverage industry, rotary vane pumps are utilized for tasks such as vacuum packaging, liquid transfer, and product handling. These pumps provide the necessary vacuum conditions for sealing packages, transferring liquids, and maintaining product integrity. Rotary vane pumps’ ability to handle both liquid and gas applications, as well as their hygienic design options, make them suitable for food and beverage processing.

– Environmental and Analytical Instruments: Rotary vane pumps are utilized in environmental monitoring and analytical instruments. They are used for tasks such as sample collection, gas analysis, and air monitoring. These pumps provide the required vacuum conditions for sample collection and analysis, ensuring accurate and reliable results. Rotary vane pumps’ compatibility with a wide range of gases and their ability to handle varying flow rates make them valuable in environmental and analytical applications.

– Medical and Healthcare: The medical and healthcare industry relies on rotary vane pumps for various applications, including vacuum-assisted wound therapy, suction devices, and medical gas systems. These pumps provide the necessary vacuum or pressure conditions required for medical procedures and equipment. Rotary vane pumps’ reliability, compact size, and compatibility with medical gases make them essential in the medical and healthcare sector.

It’s important to note that while rotary vane pumps are commonly used in these industries, specific applications and requirements may vary. Different pump models and configurations may be chosen based on factors such as flow rate, vacuum level, chemical compatibility, and operating conditions.

In summary, rotary vane pumps are relied upon by industries such as HVAC and refrigeration, automotive and manufacturing, printing and paper, laboratory and scientific research, food and beverage, environmental and analytical instruments, and medical and healthcare. Their versatility, efficiency, and ability to handle a wide range of applications make them valuable in these sectors.

How Does a Rotary Vane Pump Work?

A rotary vane pump is a type of positive displacement pump commonly used for creating vacuum or low-pressure environments. Here’s a detailed explanation of how a rotary vane pump works:

– Basic Principle: A rotary vane pump operates based on the principle of positive displacement. It uses a rotating mechanism with sliding vanes to create a continuous pumping action.

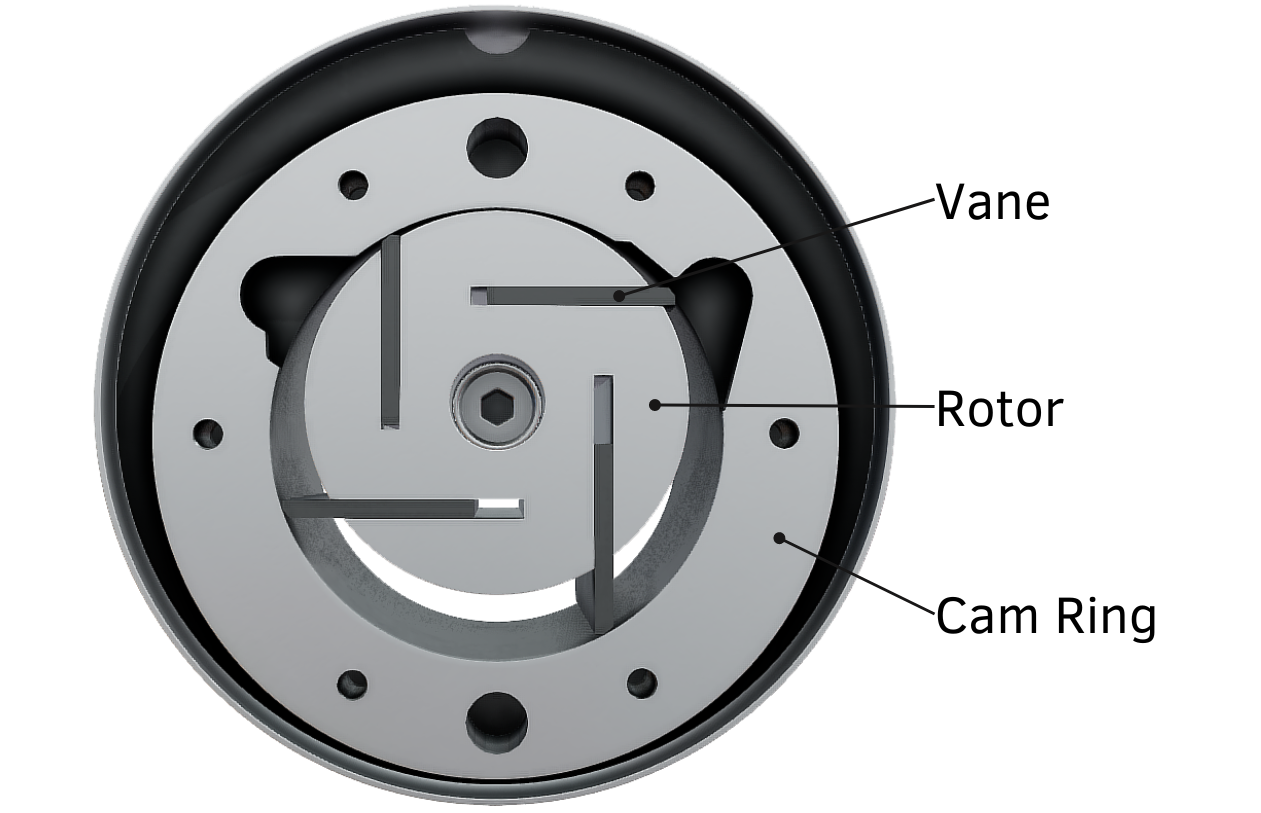

– Construction: A typical rotary vane pump consists of several key components:

– Rotor: The rotor is the central rotating element of the pump. It is typically offset from the center of the pump chamber and is connected to a drive mechanism, such as an electric motor.

– Vanes: The vanes are sliding elements that are inserted into radial slots in the rotor. They can be made of various materials, such as carbon, graphite, or synthetic materials, and are in constant contact with the pump chamber walls.

– Stator: The stator is the stationary part of the pump. It forms the pump chamber and is typically cylindrical in shape with an eccentric bore that accommodates the rotor.

– Inlet and Outlet Ports: The pump has separate inlet and outlet ports. The inlet allows the entry of gas or fluid into the pump, while the outlet facilitates the discharge of the pumped medium.

– Operation:

1. Starting Position: Initially, the rotor is positioned eccentrically within the stator, creating spaces, or cells, between the rotor vanes and the stator walls.

2. Intake Stroke: As the rotor rotates, one vane enters the intake port. This creates an expanding cell, leading to a decrease in pressure within the cell. This pressure drop causes gas or fluid to enter the pump through the inlet port and fill the expanding cell.

3. Compression Stroke: As the rotor continues to rotate, the vane moves along the stator wall, reducing the size of the cell. This compression action compresses the gas or fluid within the cell, increasing its pressure.

4. Discharge Stroke: The compressed gas or fluid is then pushed towards the outlet port as the vane moves further along the stator wall. This leads to the expulsion of the medium from the pump through the outlet port.

5. Repeat Process: The above steps are repeated continuously as the rotor continues to rotate, creating a continuous pumping action.

– Sealing and Lubrication: To ensure efficient operation and prevent leakage, rotary vane pumps require proper sealing and lubrication. The vanes slide against the stator walls, forming a seal to minimize backflow and leakage. Often, a small amount of oil or lubricant is introduced into the pump chamber to provide lubrication and maintain the seal between the vanes and the stator walls.

– Applications: Rotary vane pumps are commonly used in a variety of applications, including HVAC systems, vacuum packaging, laboratory equipment, automotive industry, and industrial processes that require vacuum or low-pressure conditions.

– It’s important to note that the performance of a rotary vane pump can be influenced by factors such as the speed of rotation, the number and dimensions of vanes, the quality of sealing, and the type of lubrication used.

In summary, a rotary vane pump operates based on the principle of positive displacement. It utilizes a rotating rotor with sliding vanes inside a stationary stator to create a continuous pumping action. The pump’s design allows for the intake, compression, and discharge of gas or fluid, making it suitable for various applications requiring vacuum or low-pressure environments.

editor by Dream 2024-05-02

by

Tags:

Leave a Reply