Product Description

Oil Lubricated Rotary Vane Vacuum Pump (RH5710)

Product Description

A typical rotary vacuum pump is comprised of a housing, a rotor and a series of radially moving vanes, which come in dry-running or lubricated versions (the latter are the most commonly used in the majority of industrial applications). The rotor is generally the only continuously moving vane vacuum pump part. There’s also a working chamber inside the housing, which is divided into 2 separate compartments by the rotor and vanes. Many vane vacuum pumps also include an inlet valve as a safety feature.

Rotary vane vacuum pumps are available in single-stage and two-stage versions. The stages refer to the number of times that compression actually occurs. Two-stage pumps are also able to attain a lower pressure than single-stage pumps, due to the fact that gas is only admitted during the high pressure stage.

Rotary vane vacuum pumps are ideally suited for a wide range of low and medium vacuum applications such as general and chemical laboratory, analytics, CHINAMFG drying, process engineering and more. A rotary vane pump works via positive displacement, which is when volumes of air or gas are confined within a closed space and are compressed when the space is mechanically reduced.

Product Parameters

| Product Model | 50/60Hz | RH5710 |

| Pumping Speed | 50Hz | 200m³/H |

| 60Hz | 240m³/H | |

| Ultimate Pressure | mbar | 0.1 |

| Inlet Diameter | G2” | |

| Voltage | 50Hz | 345-415/600-720V |

| 60Hz | 380-480/660-720V | |

| Motor Power | kW | 5.5 |

| Current (A) | 50Hz | 9.0/5.2 |

| 60Hz | 9.4/5.2 | |

| Rotate Speed | r/min | 1455/1720 |

| Noise Level | dB | 69 |

| Oil Volume | L | 6.0 |

| Net Weight | kg | 149 |

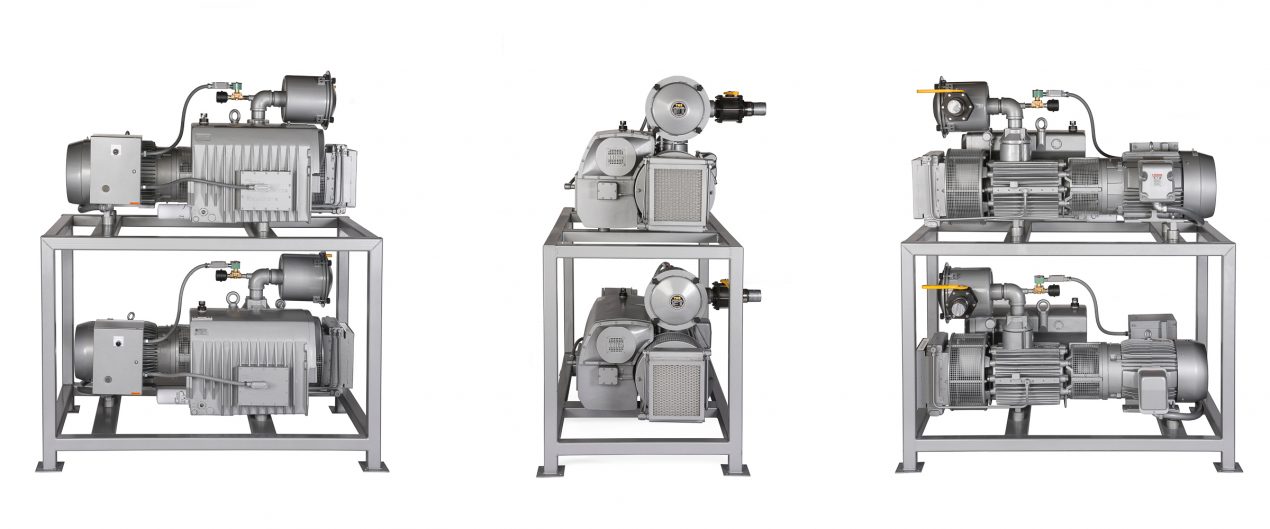

Detailed Photos

Installation Instructions

Certifications

Company Profile

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Oil or Not: | Oil |

|---|---|

| Structure: | Rotary Vacuum Pump |

| Exhauster Method: | Kinetic Vacuum Pump |

| Vacuum Degree: | High Vacuum |

| Work Function: | Maintain the Pump |

| Working Conditions: | Dry |

| Samples: |

US$ 2275/Set

1 Set(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Are There Oil-Free Rotary Vane Pump Options Available?

Yes, there are oil-free rotary vane pump options available in the market. These pumps are designed to operate without the need for lubricating oil, offering certain advantages and applications where oil contamination is a concern. Here’s a detailed explanation:

– Dry Vane Technology: Oil-free rotary vane pumps, also known as dry vane pumps, utilize specialized dry vane technology. Instead of relying on lubricating oil to create a seal and reduce friction, these pumps use self-lubricating materials and innovative design features to achieve efficient operation without oil.

– Reduced Contamination Risk: One of the primary advantages of oil-free rotary vane pumps is that they eliminate the risk of oil contamination. In certain applications, such as in the food and beverage industry, pharmaceutical production, or cleanroom environments, maintaining a completely oil-free and contaminant-free operation is critical. Oil-free rotary vane pumps address these requirements and ensure the purity and integrity of the process or product being handled.

– Environmental Friendliness: Oil-free rotary vane pumps are considered more environmentally friendly compared to their oil-lubricated counterparts. The elimination of oil lubrication means there is no risk of oil leaks or spills, reducing the potential impact on the environment. These pumps also eliminate the need for oil changes and disposal, resulting in lower maintenance and disposal costs.

– Lower Operating Costs: Oil-free rotary vane pumps can offer cost advantages in terms of operating expenses. Since they do not require oil lubrication, there is no need to purchase, monitor, or replace oil. This can result in savings over the pump’s lifetime. Additionally, oil-free pumps often have lower maintenance requirements, as there is no need to monitor oil levels, change oil, or replace oil filters.

– Application Flexibility: Oil-free rotary vane pumps are suitable for a range of applications where oil contamination must be avoided. They find application in industries such as food and beverage, pharmaceuticals, medical devices, laboratory research, electronics manufacturing, and other sensitive environments. These pumps can handle both gas and some liquid applications, providing versatility in various processes.

– Considerations: While oil-free rotary vane pumps offer several advantages, it’s important to consider certain factors when choosing these pumps. They may have slightly different operating characteristics compared to oil-lubricated pumps, such as lower ultimate vacuum levels or reduced performance in high-pressure applications. It’s crucial to assess the specific requirements of the application and consult the manufacturer’s specifications to ensure the chosen oil-free rotary vane pump meets the desired performance criteria.

– Alternative Technologies: In cases where oil-free rotary vane pumps may not be suitable, alternative technologies such as dry screw pumps or dry claw pumps can be considered. These pumps also offer oil-free operation and have their own unique advantages and applications.

In summary, oil-free rotary vane pumps are available and offer benefits such as eliminating oil contamination, environmental friendliness, reduced operating costs, and application flexibility. They are particularly valuable in industries where maintaining an oil-free environment is critical. Understanding the specific requirements of the application and consulting with pump manufacturers can help in selecting the appropriate type of pump for the desired operation.

Can Rotary Vane Pumps Create a Deep Vacuum?

Rotary vane pumps are capable of creating a vacuum, but the depth of the vacuum they can achieve is limited compared to other types of vacuum pumps. Here’s a detailed explanation:

Rotary vane pumps utilize a positive displacement mechanism to create a vacuum. As the rotor rotates, the vanes slide in and out of the rotor slots, creating expanding and contracting chambers. This action allows the pump to draw in gas or fluid from the inlet port and then expel it through the outlet port.

While rotary vane pumps can achieve relatively high vacuum levels, they are not typically designed to create extremely deep vacuums. The ultimate vacuum level that a rotary vane pump can achieve depends on several factors, including the specific pump design, the quality of the sealing surfaces, the lubrication system, and the operating conditions.

In general, rotary vane pumps can achieve vacuum levels in the range of a few millibars (thousandths of atmospheric pressure) or slightly lower. However, they may struggle to reach the ultra-high vacuum levels required in certain applications, such as semiconductor manufacturing or scientific research.

For applications that demand deeper vacuums, other types of pumps, such as turbomolecular pumps or cryogenic pumps, are typically employed. These pumps are specifically designed to operate in the high-vacuum or ultra-high-vacuum range and can achieve significantly lower pressures than rotary vane pumps.

It’s important to consider the specific requirements of your application when selecting a vacuum pump. If you need to create a deep vacuum, you may need to explore alternative pump technologies that are better suited to achieve the desired vacuum level.

In summary, while rotary vane pumps can create a vacuum, their capability to achieve deep vacuums is limited compared to specialized high-vacuum pumps. The ultimate vacuum level achievable with a rotary vane pump depends on various factors, and if ultra-high vacuum levels are required, alternative pump technologies should be considered.

editor by Dream 2024-05-07

Leave a Reply