Product Description

Product Parameters

| Model | 2xz-0.5 | 2xz-1 | 2xz-2 | 2xz-4 | |

| Pumping Speed L/S(m³/h) | 0.5(1.8) | 1(3.6) | 2(7.2) | 4(14.4) | |

| Extreme Pressure(Pa) | Partial Pressure | ≤6×10-2 | ≤6×10-2 | ≤6×10-2 | ≤6×10-2 |

| Full Pressure | ≤1.33 | ≤1.33 | ≤1.33 | ≤1.33 | |

| Rotating Speed r/min(50/60Hz) | 1400/1700 | 1400/1700 | 1400/1700 | 1400 | |

| Voltage(v) | 220 | 220/380 | 220/380 | 220/380 | |

| Motor Power(kw) | 0.18 | 0.25 | 0.37 | 0.55 | |

| Inlet Diameter (Outer Diameter)mm | G3/8(∅12) | G3/8(∅12) | G3/4(∅12) | G3/4(∅12) | |

| KF-16 | KF-16 | KF-25 | KF-25 | ||

| Noise(dBA) | 62 | 62 | 63 | 64 | |

| Oil volume (L) | 0.6 | 0.7 | 1 | 1.1 | |

| Size(mm) | 538*215*360 | 538*215*360 | 580*215*367 | 580*215*367 | |

| Gross/Net Weight(kg) | 17/16 | 18/17 | 22/20 | 25/22 | |

| Model | 2xz-2B | 2xz-4B | 2xz-6B | 2xz-8B | 2xz-15B | 2xz-25B | |

| Pumping Speed L/S(m³/h) | 2(7.2) | 4(14.4) | 6(21.6) | 8(28.8) | 15(54) | 25(90) | |

| Extreme Pressure(Pa) | Partial Pressure | ≤4×10-2 | ≤4×10-2 | ≤4×10-2 | ≤4×10-2 | ≤4×10-2 | ≤4×10-2 |

| Full Pressure | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | |

| Rotating Speed r/min(50/60Hz) | 1400/1700 | 1400/1700 | 1400/1700 | 1400/1700 | 1400/1700 | 1400/1700 | |

| Voltage(v) | 220/380 | 220/380 | 220/380 | 380 | 380 | 380 | |

| Motor Power(kw) | 0.37 | 0.55 | 0.75 | 1.5 | 1.5 | 2.2 | |

| Inlet Diameter (Outer Diameter)mm | G3/4 | G3/4 | ∅30 | ∅40 | ∅40 | ∅50 | |

| KF-25 | KF-25 | KF-25 | KF-40 | KF-40 | KF-50 | ||

| Noise(dBA) | 65 | 66 | 68 | 70 | 72 | 74 | |

| Oil volume (L) | 0.8 | 0.95 | 1-1.2 | 2.3-2.5 | 2.8-3.3 | 5.5-6.5 | |

| Size(mm) | 580*215*367 | 580*215*367 | 670*240*320 | 720*270*390 | 770*270*390 | 900*320*550 | |

| Gross/Net Weight(kg) | 22/20 | 25/22 | 46/40 | 68/52 | 75/62 | 90/70 | |

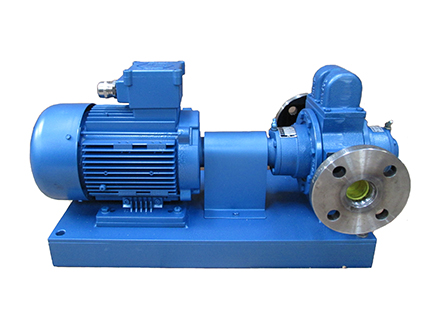

Product Description

Rotary Vane Vacuum Pump is the basic equipment used to remove gas from sealed containers. It can be used alone, also can be used for booster pump, diffusion pump, molecular pump before the pump, maintenance pump, titanium pump pre-pumping pump, It can be used for vacuum drying, CHINAMFG drying, vacuum degassing, vacuum packaging, vacuum adsorption, vacuum forming, coating, food packaging, printing, sputtering, vacuum casting, instruments, instruments, refrigerators, air conditioning lines and laboratories and other vacuum operations and supporting use.

· Due to the thorough low noise design and precision machining, so as to achieve low noise

· Specially designed gas valve is prepared to prevent the pump oil from mixing with water and prolong the service time of the pump oil

· Adopt similar product design, small size, light weight, low noise, easy to start

· Equipped with vacuum drying oven, freeze-drying machine, printing machinery

· It can be equipped with small-caliber adapter, KF interface and flange interface

Application

· Rotary Vane Vacuum Pump corollary use with freezer dryer to reach vacuum state, it’s an essential corollary equipment in medicine CHINAMFG drying, biology, food industry and agricultural products deep processing

· Rotary Vane Vacuum Pump corollary use with vacuum drying oven for maintaining vacuum state inside the oven, they mainly applies in powder drying and baking in vacuum condition

Company Profile

Packaging & Shipping

FAQ

Q1. What is your products range?

• Industry water chiller, recirculating cooling chiller, rotary evaporator, alcohol recovery equipment, short path distillation kit, glass molecular distillation equipment, falling film evaporator, jacketed glass reactor and other lab equipment.

Q2. Are you trading company or manufacturer?

• We are professional manufacture of lab equipment and we have our own factory.

Q3. Do you provide samples? Is it free?

• Yes, we could offer the sample. Considering the high value of our products, the sample is not free, but we will give you our best price including shipping cost.

Q4. Do you have warranty?

• Yes, we offer 1 year warranty for the spare part.

Q5. How long is your delivery time?

• Generally it is within 7 working days after receiving the payment if the goods are in stock. Or it is 15 working days if thegoods are not in stock, depending on order quantity.

Q6. What is your terms of payment?

• Payment≤15,000USD, 100% in advance. Payment≥15,000USD, 70% T/T in advance, balance before shipment.

(If you are concerned about payment security for the first order, we advise you can place Trade Assurance Order via Alibaba. you will get 100% payment refund if we can’t meet agreed delivery time.)

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Online Service Support |

|---|---|

| Warranty: | 1 Year |

| Oil or Not: | Oil |

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can rotary vane pumps be used in medical or laboratory applications?

Yes, rotary vane pumps can be used in medical or laboratory applications. Rotary vane pumps are a type of positive displacement pump that use vanes mounted on a rotor to create suction and move fluids. They are commonly used in a variety of industries, including medical and laboratory settings, due to their reliable performance and ability to handle a wide range of fluids.

In medical applications, rotary vane pumps can be used for tasks such as vacuum aspiration, vacuum filtration, and vacuum drying. They are often employed in medical laboratories for sample preparation, where they help create vacuum conditions necessary for various processes, such as evaporation, distillation, and filtration. Rotary vane pumps can also be used in medical devices such as vacuum ovens, freeze dryers, and vacuum concentrators.

In laboratory settings, rotary vane pumps are utilized for numerous applications. They are commonly used in vacuum systems to create and maintain the necessary vacuum levels for experiments, particularly when working with sensitive samples or volatile substances. Rotary vane pumps can generate a high vacuum level and provide a stable vacuum source, making them suitable for tasks such as rotary evaporation, degassing, and gas analysis.

It’s worth noting that when rotary vane pumps are used in medical or laboratory applications, they need to meet certain requirements and standards to ensure safety and reliability. For example, pumps used in medical settings may need to comply with medical device regulations and standards, while pumps used in laboratories may need to meet specific requirements for chemical compatibility, noise levels, and performance specifications.

In summary, rotary vane pumps are well-suited for medical and laboratory applications due to their ability to create and maintain vacuum conditions. They offer reliable performance and versatility, making them a popular choice in various scientific and healthcare settings.

How Do You Maintain and Service a Rotary Vane Pump?

Maintaining and servicing a rotary vane pump is essential to ensure its optimal performance and prolong its operational life. Here’s a detailed explanation of the maintenance and servicing procedures for a rotary vane pump:

– Regular Inspection: Perform regular visual inspections of the pump to check for any signs of wear, leaks, or damage. Inspect the pump housing, vanes, seals, and connections. Look for any loose or worn parts that may require attention.

– Lubrication: Proper lubrication is crucial for the smooth operation of a rotary vane pump. Follow the manufacturer’s guidelines regarding the type and frequency of lubrication. Typically, the pump requires lubrication with a suitable oil or grease. Ensure that the lubrication level is adequate, and monitor the condition of the lubricant. Replace or replenish the lubricant as recommended.

– Vane Replacement: The vanes in a rotary vane pump can wear down over time and may need to be replaced periodically. Inspect the vanes regularly and look for signs of wear, such as cracks or reduced thickness. Replace the vanes if necessary, following the manufacturer’s instructions.

– Cleaning: Keep the pump and its components clean to prevent the buildup of debris or contaminants. Use a suitable cleaning agent and a soft cloth or brush to clean the pump housing, vanes, and other parts. Avoid using harsh chemicals or abrasive materials that may damage the pump surfaces.

– Filter Maintenance: If the rotary vane pump has an inlet filter, inspect and clean or replace it regularly. The filter prevents debris from entering the pump and affecting its performance. Follow the manufacturer’s recommendations for filter maintenance and replacement intervals.

– Seals and Gaskets: Check the seals and gaskets of the pump for signs of wear or leakage. Replace any damaged or worn seals to maintain proper sealing and prevent fluid or gas leaks.

– Motor and Electrical Connections: Inspect the motor and electrical connections of the pump for any loose or damaged wires. Ensure that the electrical connections are secure and free from corrosion. If any issues are found, consult a qualified technician or electrician for repairs.

– Operating Conditions: Ensure that the pump is operated within its specified operating conditions. Avoid subjecting the pump to excessive temperatures, pressures, or fluid viscosity that may exceed its capabilities. Adhere to the recommended operating parameters to prevent premature wear or damage to the pump.

– Service and Calibration: Periodically, consider having the rotary vane pump serviced and calibrated by a qualified technician. This ensures that the pump is operating at its optimal performance and accuracy. The technician can perform maintenance tasks, inspect internal components, and make any necessary adjustments or repairs.

It’s important to consult the manufacturer’s guidelines and recommendations specific to your rotary vane pump model for detailed maintenance and servicing instructions. Adhering to these guidelines and performing regular maintenance will help keep the pump in good working condition and extend its service life.

editor by Dream 2024-05-09

by

Leave a Reply