Product Description

COMPANY SHOW:

20 Years

ZiBoZhuoXin Pump Industry co,.Ltd is located in a century industrial city known as the Pump Capital of China—HangZhou city, ZheJiang Province. Has over 20 years’ experience of manufacturing vacuum pumps and 10+ years’ experience of exporting.

Various products

We can suppply all type of vacuum pumps and spare parts in China, 2BV/2BEA/2BEC/SK/2SK/JZJ2B/ etc, and other industrial machine;

24 Hours

Please do not hestiate to contact us if have any urgent matters,each of your inquiries will be taken into account and get our response within 24 hours.

Product Main feature:

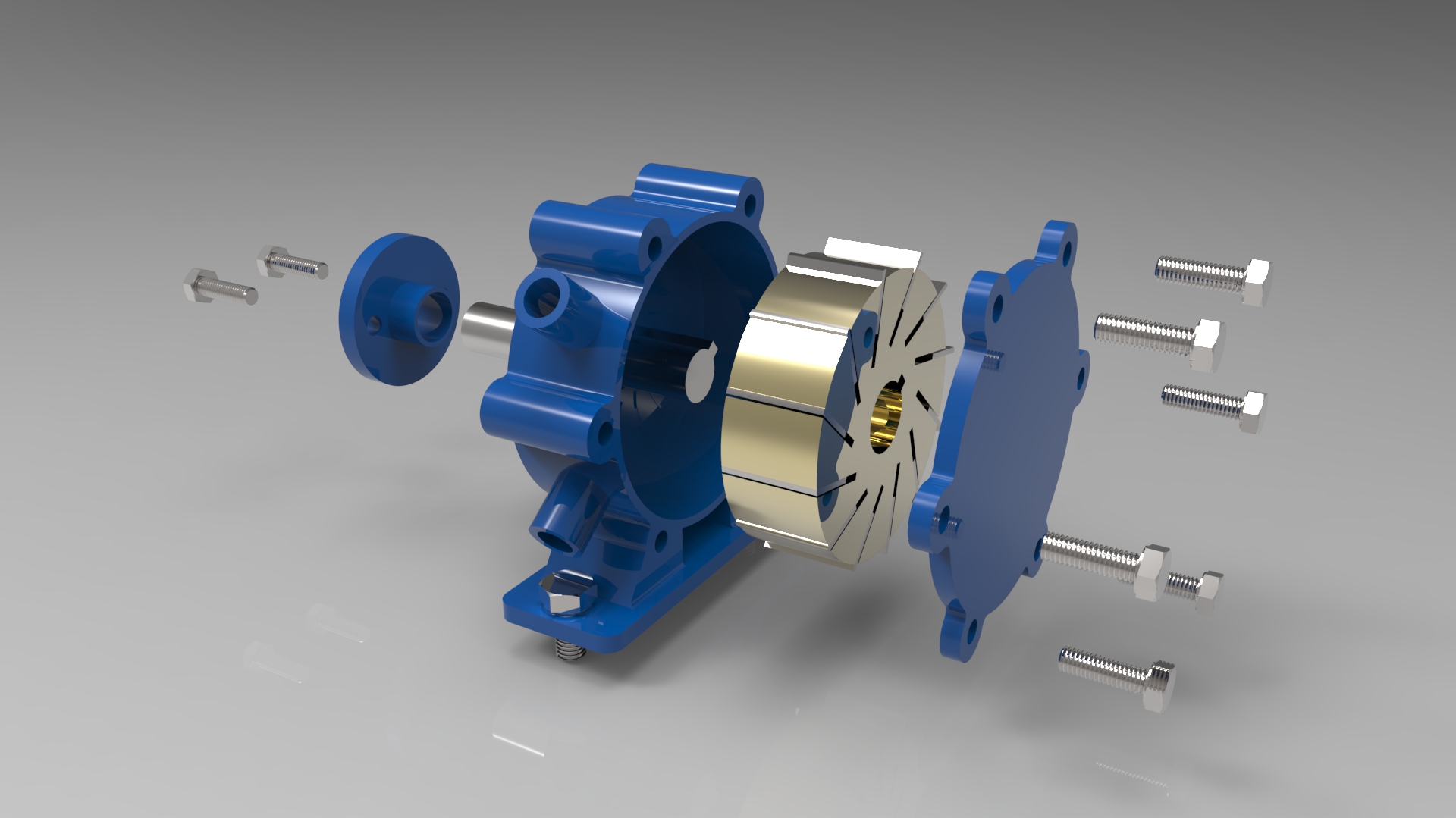

1, Product introduction of XD rotary vane vacuum pump:

1. XD rotary vane vacuum pumps are single-stage oil sealed rotary vane vacuum pumps, which are the basic equipment to obtain vacuum. The working principle is shown.

2. The suction port of XD rotary vane vacuum pump is equipped with a coarse filter with wire mesh. It can prevent the CHINAMFG foreign dust particles from being sucked into the pump chamber. The oil separator is equipped with an exhaust transition device with high efficiency oil-gas separation effect. When the pump is stopped, the suction valve built in the suction port isolates the pump from the system to prevent the pump oil from returning to the pumped system. The pump is air-cooled. All pumps of XD rotary vane vacuum pump are driven by direct connected motor through elastic coupling.

2, Application scope of XD rotary vane vacuum pump:

1. XD rotary vane vacuum pump is suitable for vacuum pumping of closed system. Such as vacuum packaging, vacuum forming, vacuum suction.

2. Inlet pressure range: 1 PA, beyond this range, there will be oil mist at the exhaust port of vacuum pump. XD rotary vane vacuum pump working environment temperature and suction gas temperature should be between 5 ºC and 40 ºC.

3. XD rotary vane vacuum pump can not pump water or other liquids. Do not remove explosive, flammable, high oxygen content, corrosive gas.

4. Generally, the motor supplied is not explosion-proof. If explosion-proof or other special requirements are required, the motor must comply with relevant standards.

| Model | XD-571 | XD-016 | XD-571 | XD-571 | XD-040 | XD-063 | XD-100 | XD-160 | XD-250 |

| displacement capacity(m3/h) | 10 | 16 | 20 | 25 | 40 | 63 | 100 | 160 | 250 |

| Limited pressure(Pa) | 2×102 | ||||||||

| Power(kw) | 0.37 | 0.37 | 0.75 | 0.75 | 1.1 | 1.5 | 3 | 4 | 7.5 |

| pump speed(r.p.m) | 1440 | 1440 | 2800 | 2800 | 1440 | 1440 | 1440 | 1440 | 1440 |

| Oil loading(L) | 0.5 | 0.5 | 0.5 | 1 | 1.5 | 2 | 4 | 9 | 9 |

| Air inlet size | G½ | G½ | G½ | G1¼ | G1¼ | G1¼ | G1¼ | G2 | G2½ |

| pump weight(kg) | 16 | 18 | 19 | 19 | 60 | 22 | 115 | 145 | 200 |

| Voltage(V) | 380/220 | 380/220 | 380/220 | 380/220 | 380/220 | 380 | 380 | 380 | 380 |

FAQ

Q: What’s your MOQ?

A: One set;

Q: What are the causes of no flow or insufficient flow of centrifugal pump?

A: There is air in the suction pipe or pump, which needs to be discharged. Air leakage is found in the suction pipeline, and the leakage is repaired. If the valve of suction line or discharge line is closed, relevant valve shall be opened. If the suction height is too high, recalculate the installation height. The suction line is too small or blocked.

Q: How to resist cavitation in centrifugal pump?

A: Improve the structure design from the suction to the impeller of the centrifugal pump;Adopt double stage suction impeller and use anti-cavitation material;

Q:What is the function of rubber ball in water ring vacuum pump?

A: Rubber ball in water ring vacuum pump, the correct name is called rubber ball valve. Its role is to eliminate the pump equipment in the operation process of the phenomenon of over compression or insufficient compression.

Q:How long is warranty?

A:One year formain construction warranty.

Q:How can I pay for my items? What is the payment you can provide

A:Usually by T/T, 30%-50% deposit payment once PI/Contract confirmed, then the remaining balance will be paid after inspection and before shipment via T/T or L/C;

Welcome client from home and abroad to contact us for future cooperation.

Detail size drawing and install drawing please contact our sales in charge to get;

Key:nash/simense/refurish/vacuum pumps/HangZhou CHINAMFG pump/liquid ring vacuum pump compressor; /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Oil or Not: | Oil |

|---|---|

| Structure: | Rotary Vacuum Pump |

| Exhauster Method: | Kinetic Vacuum Pump |

| Vacuum Degree: | High Vacuum |

| Work Function: | Mainsuction Pump |

| Working Conditions: | Dry |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

What Is the Energy Efficiency of Rotary Vane Pumps?

The energy efficiency of rotary vane pumps can vary depending on several factors, including the design of the pump, operating conditions, and specific application requirements. Here’s a detailed explanation of the energy efficiency considerations for rotary vane pumps:

– Design Efficiency: The design of the rotary vane pump can significantly impact its energy efficiency. Modern rotary vane pumps are designed with efficiency in mind, incorporating features such as optimized rotor profiles, improved sealing mechanisms, and reduced internal leakage. These design enhancements aim to minimize energy losses and maximize the pump’s overall efficiency.

– Motor Efficiency: The motor driving the rotary vane pump plays a crucial role in its energy efficiency. High-efficiency motors, such as those meeting premium efficiency standards (e.g., NEMA Premium Efficiency or IE3), can contribute to the overall energy efficiency of the pump system. Using motors with appropriate power ratings and matching the motor size to the pump’s requirements can help optimize energy consumption.

– Operating Point: The operating point at which the rotary vane pump operates can impact its energy efficiency. Pumps often have an optimum operating range where they achieve the highest efficiency. Operating the pump within this range can help minimize unnecessary energy consumption. It’s important to consider the system requirements and select a pump that can operate efficiently under the expected operating conditions.

– Control and Automation: Implementing effective control and automation strategies can enhance the energy efficiency of rotary vane pump systems. Variable frequency drives (VFDs) or speed control mechanisms can adjust the pump’s speed or output to match the required flow rate, reducing energy wastage. Additionally, incorporating sensors and control algorithms that optimize pump operation based on demand can further improve energy efficiency.

– System Design and Integration: The overall system design and integration can influence the energy efficiency of rotary vane pumps. Proper sizing of the pump based on the system requirements, minimizing pressure losses in the piping network, and optimizing the layout of the system components can all contribute to improved energy efficiency. Considering the system as a whole and implementing energy-saving practices can result in significant energy savings.

– Maintenance and Performance Monitoring: Regular maintenance and performance monitoring are essential for maintaining the energy efficiency of rotary vane pumps. Ensuring proper lubrication, monitoring for leaks or wear, and addressing any performance issues promptly can prevent energy losses due to degraded pump performance. Periodic performance assessments and efficiency measurements can help identify opportunities for optimization and energy-saving initiatives.

It’s important to note that the energy efficiency of rotary vane pumps can vary among different pump models and manufacturers. When selecting a rotary vane pump, it is advisable to review the manufacturer’s specifications, efficiency data, and performance curves to evaluate the pump’s energy efficiency characteristics.

Overall, by considering design efficiency, motor efficiency, operating point, control strategies, system design, and maintenance practices, it is possible to enhance the energy efficiency of rotary vane pumps and reduce energy consumption in various applications.

What Are the Typical Applications of Rotary Vane Pumps?

Rotary vane pumps find application in various industries and sectors due to their versatility and reliable performance. Here’s a detailed explanation of the typical applications of rotary vane pumps:

– Industrial Manufacturing: Rotary vane pumps are commonly used in industrial manufacturing processes. They are employed for tasks such as vacuum packaging, vacuum drying, vacuum distillation, and vacuum filtration. The pumps assist in creating and maintaining the necessary vacuum levels for these manufacturing operations.

– HVAC Systems: Rotary vane pumps play a crucial role in heating, ventilation, and air conditioning (HVAC) systems. They are utilized for tasks such as evacuating air and moisture from refrigeration and air conditioning systems during installation or maintenance. Rotary vane pumps ensure proper system performance and prevent issues like refrigerant contamination.

– Laboratory and Scientific Research: Rotary vane pumps are widely used in laboratory settings and scientific research facilities. They are employed in applications such as vacuum ovens, freeze drying, sample preparation, and vacuum distillation. Rotary vane pumps provide the necessary vacuum conditions for experiments, sample processing, and equipment operation.

– Medical and Healthcare: Rotary vane pumps find application in the medical and healthcare industry. They are used in medical devices such as vacuum suction units, blood analyzers, and laboratory equipment. Rotary vane pumps assist in creating a vacuum for various medical procedures, diagnostics, and research activities.

– Automotive: Rotary vane pumps are utilized in automotive systems, particularly in vehicles with diesel engines. They are commonly employed as vacuum pumps for brake boosters, which enhance braking performance. Rotary vane pumps ensure reliable vacuum supply for effective braking, contributing to vehicle safety.

– Printing and Packaging: Rotary vane pumps are employed in printing and packaging industries. They are used for tasks such as vacuum hold-down in printing presses and vacuum packaging of products. Rotary vane pumps facilitate the precise handling of paper, cardboard, and other materials during printing and packaging processes.

– Food and Beverage Processing: Rotary vane pumps find application in the food and beverage industry. They are utilized for tasks such as vacuum packaging of perishable products, vacuum degassing of liquids, and vacuum filling of bottles or containers. Rotary vane pumps contribute to extending the shelf life of food products and ensuring their quality.

– Environmental Applications: Rotary vane pumps are utilized in environmental applications such as air sampling and monitoring equipment. They assist in creating a vacuum for sampling air pollutants, analyzing air quality, and conducting environmental research.

– Semiconductor Manufacturing: Although rotary vane pumps may not be suitable for ultra-high vacuum applications in semiconductor manufacturing, they still find utility in certain stages of the process. They are often used for tasks such as load-lock operations, wafer handling, and general vacuum needs that do not require extremely low pressures.

– Other Applications: Rotary vane pumps have additional applications in areas such as power generation, oil and gas, chemical processing, pharmaceutical production, and wastewater treatment. They are employed for various tasks involving vacuum generation, fluid handling, and system evacuation.

In summary, rotary vane pumps have diverse applications across industries, including industrial manufacturing, HVAC systems, laboratory research, medical and healthcare, automotive, printing and packaging, food and beverage processing, environmental monitoring, and more. Their reliable performance, versatility, and ability to create vacuum make them valuable in numerous applications and processes.

editor by Dream 2024-05-10

by

Tags:

Leave a Reply